Robotised grinding - precision, efficiency and savings for your business

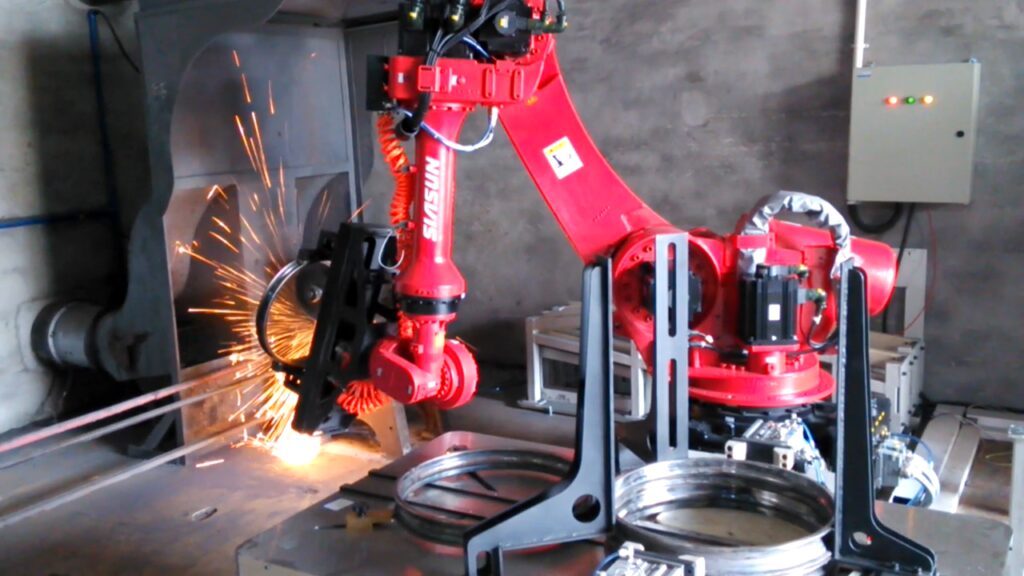

We design and implement complex robotic grinding stations that combine the latest technology with our many years of experience in building production lines.

Trust our experience - we build grinding stations from A to Z

We offer proven robotic workstations for manufacturing industries

Comprehensive implementation of robotic grinding systems

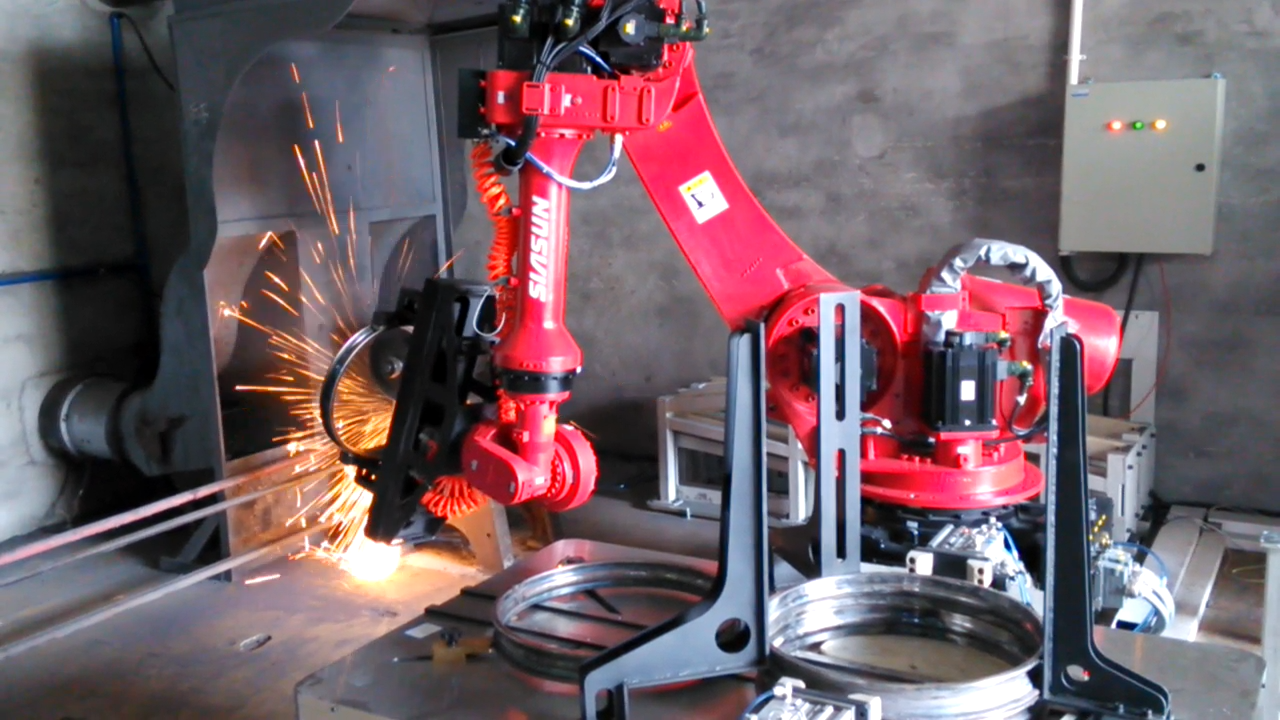

Our company specialises in the design and implementation of state-of-the-art robotic systems for surface grinding of different types of materials such as steel, aluminium, wood or plastics. We offer:

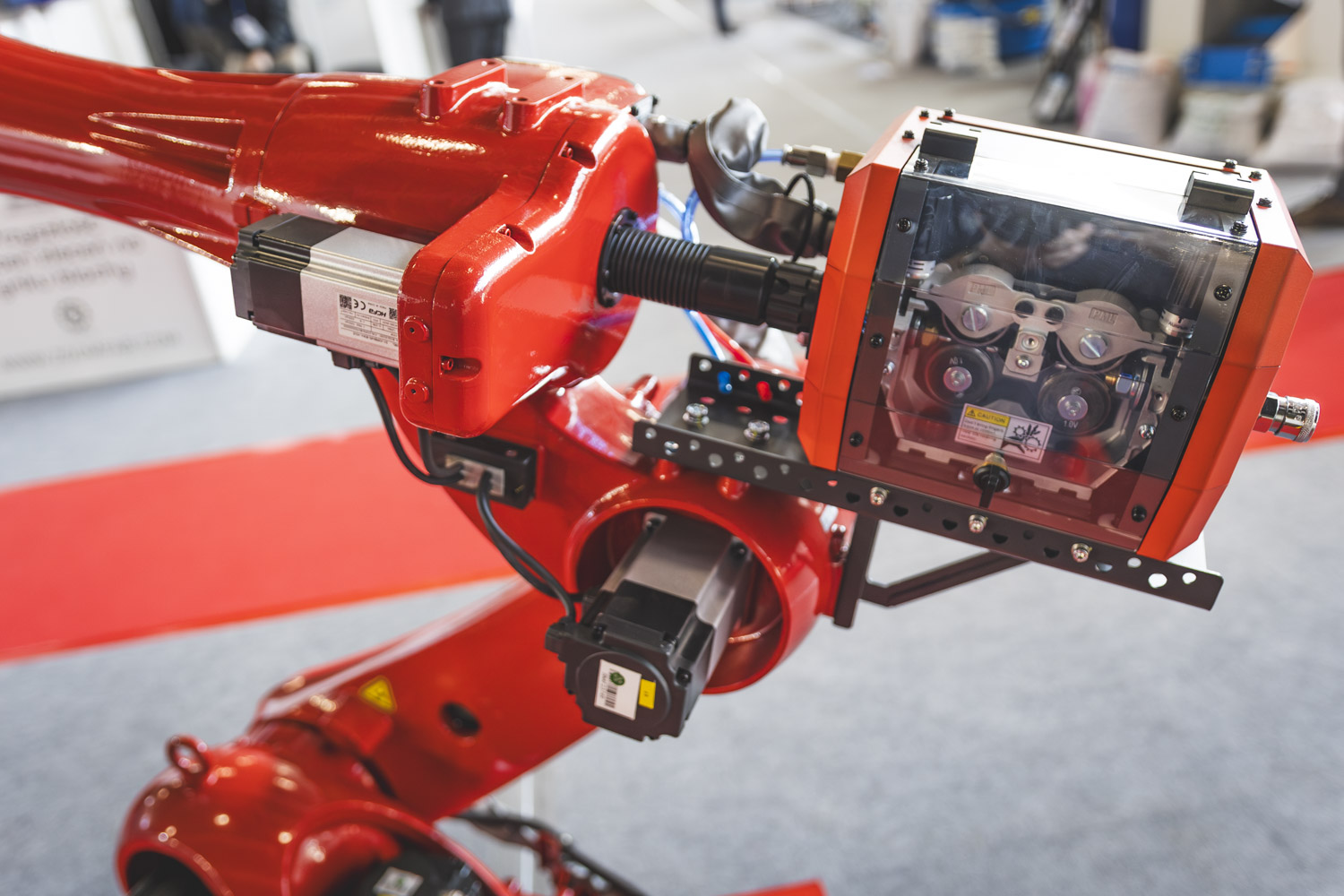

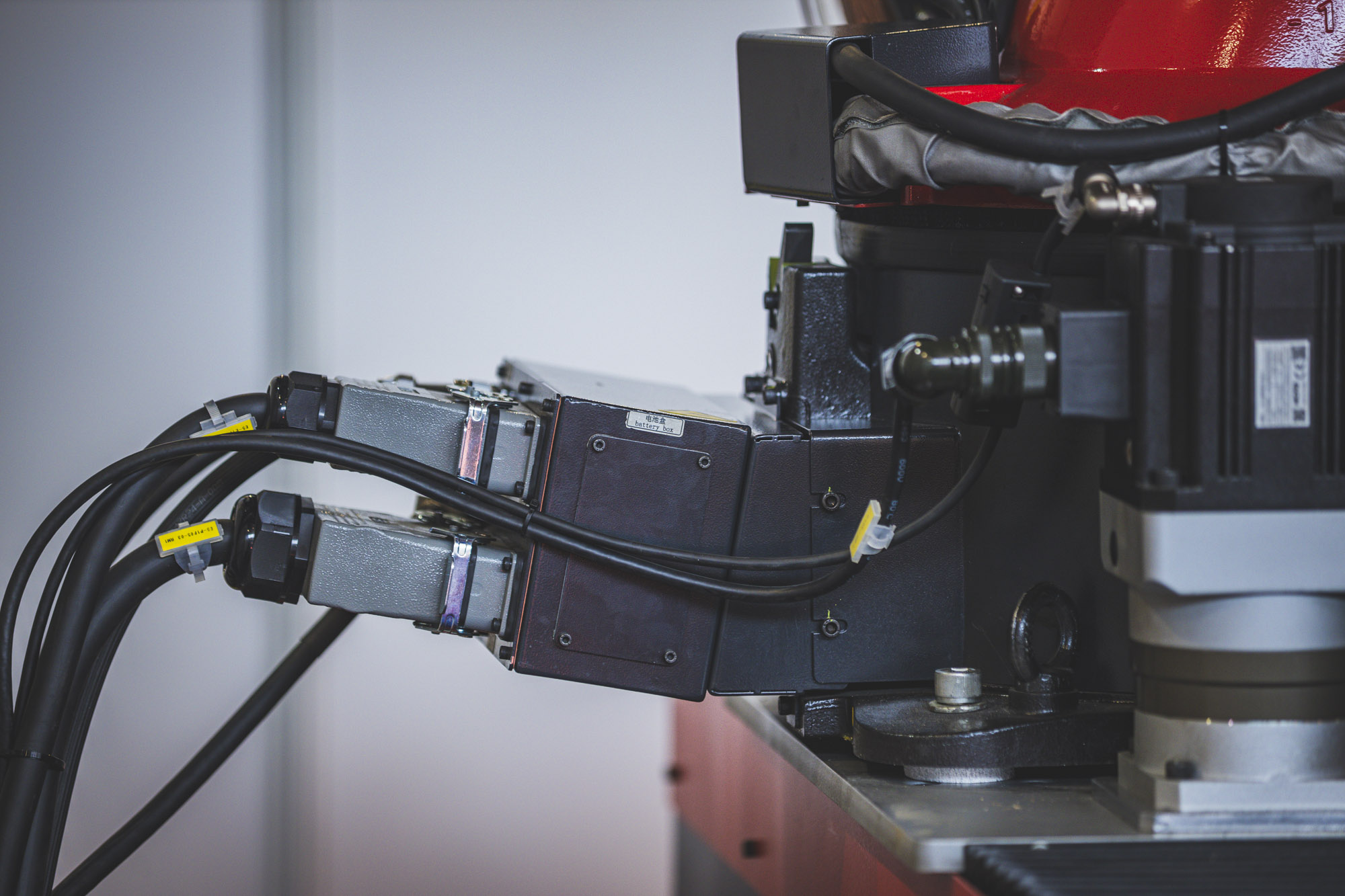

Selection of suitable Siasun robots and grinding accessories.

Designing customised workstations to meet specific client needs.

Integration with existing production lines.

Programming of the robot and configuration of the entire system.

Installation and commissioning of the workstation at the customer's site.

Operator training and full technical support.

Our solutions cover all stages - from customer needs analysis to design and after-sales service.

Why implement robotic grinding stations?

There are many benefits to implementing our solutions:

Precision and repeatability: The robots provide a perfect surface finish with every operation.

Increasing productivity: Robots work 24/7, eliminating downtime and speeding up production processes.

Reducing labour costs: Replacing manual operations with robots allows for a rapid return on investment - in as little as 1.5-2 years.

Occupational safety: Process automation reduces the risk of machine-related accidents.

Production flexibility: Adaptability of the system to different materials and changing market needs.

Our workstations are designed to maximise production processes and increase your company's competitiveness.

Siasun robots and years of experience in the construction of stands

Siasun robots are some of the best equipment on the market - reliable, precise and economical. Thanks to our exclusivity in the Polish market, we offer them at a competitive price, allowing a quick return on investment. We combine this technology with our experience in building large production lines, creating complete workstations tailored to the customer's specific needs.

Realised projects - our business card

We are proud to present examples of our implementations that have helped our clients achieve tangible business benefits

Packaging system

6-head saw

Saw with feeder

Ready for collaboration?

Don't wait any longer! Contact us today and find out how we can help your business reach new levels of productivity.

Make an appointment for a consultation

Robotised workstations

Why us?

We are a company that offers end-to-end construction of robotic workstations from A to Z, eliminating the need for external contractors and speeding up projects. Our experience in building production lines allows us to transfer proven solutions to modern robotic workstations, ensuring high quality and efficiency.

In addition, as the exclusive distributor of Siasun robots in Poland, we offer our customers access to market-leading robotic technology at more competitive prices, without having to compromise on quality and performance.

-

Experience in building production lines Years of experience in the design and construction of production lines allow us to implement proven and innovative solutions, tailored to the specific needs of the company.

-

Individual approach to the customer We understand that every business is different, which is why our solutions are always tailored to our clients' individual needs and business goals, ensuring maximum satisfaction.

-

Competitive prices Our solutions offer excellent value for money, so you can modernise your processes without going over budget.

-

Exclusivity for Siasun robots in Poland We are the only company in Poland to offer Siasun robots that combine unparalleled quality with attractive pricing, giving our customers exceptional value and a competitive advantage.

-

Guarantee and fast service We guarantee a fast service with a fair guarantee, safeguarding your investment and ensuring the uninterrupted operation of your production facility.

-

Comprehensive service We offer full support - from consultation to design to service - ensuring seamless implementations and business continuity.

Your production

at a new level

Here's how robotisation is changing the face of your business - concrete data that speaks for itself.

Tailor-Made Complex Stations

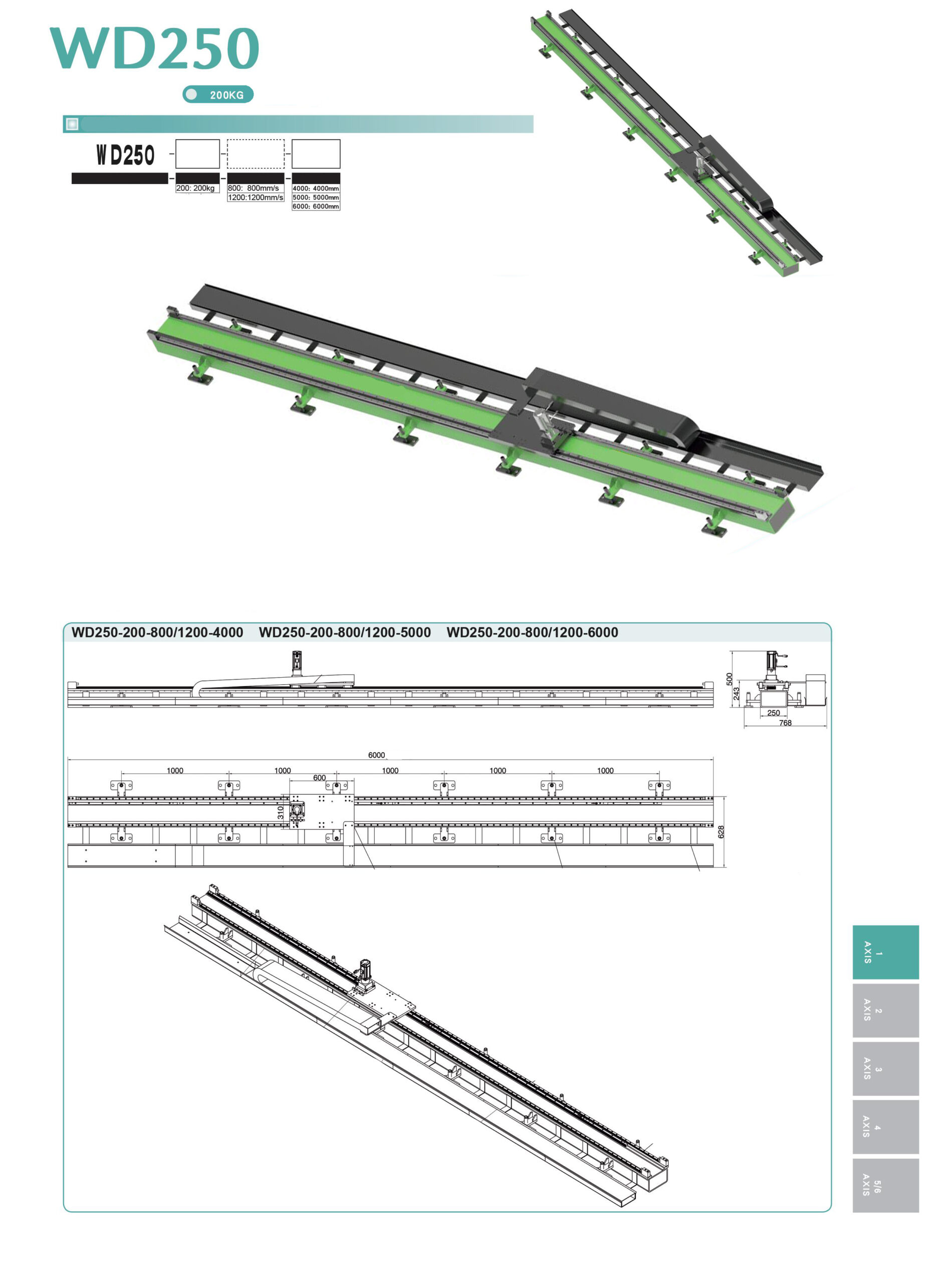

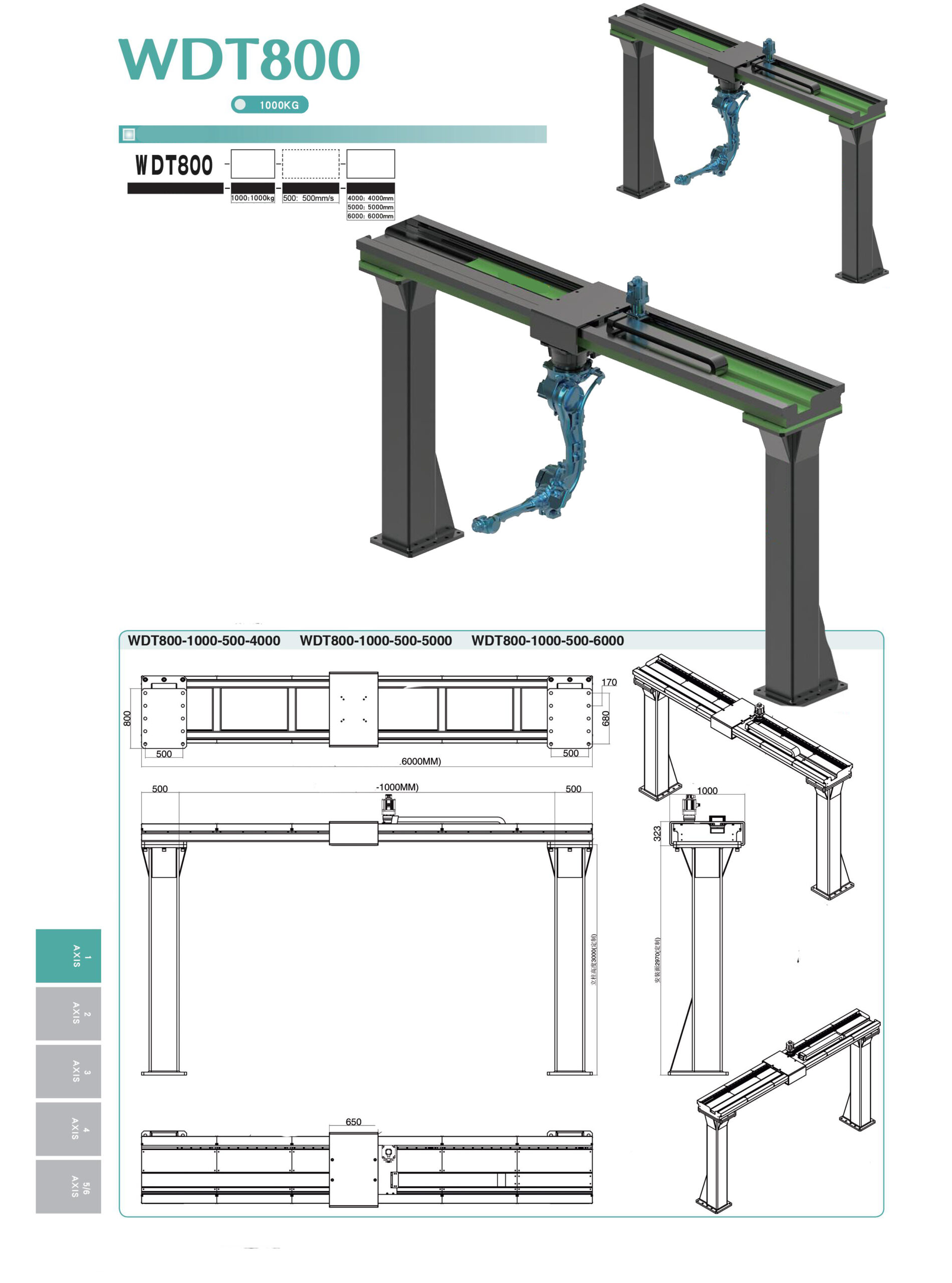

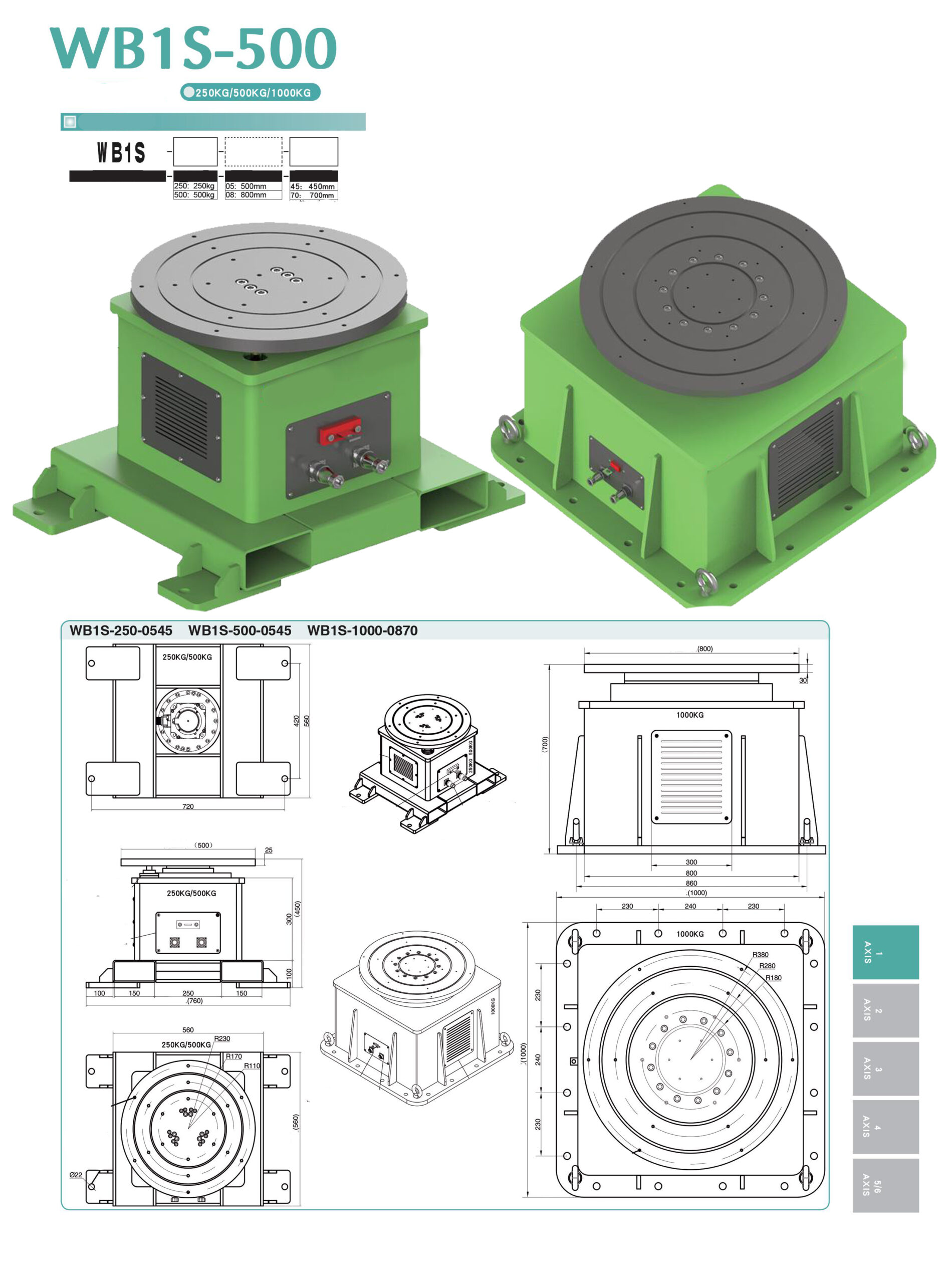

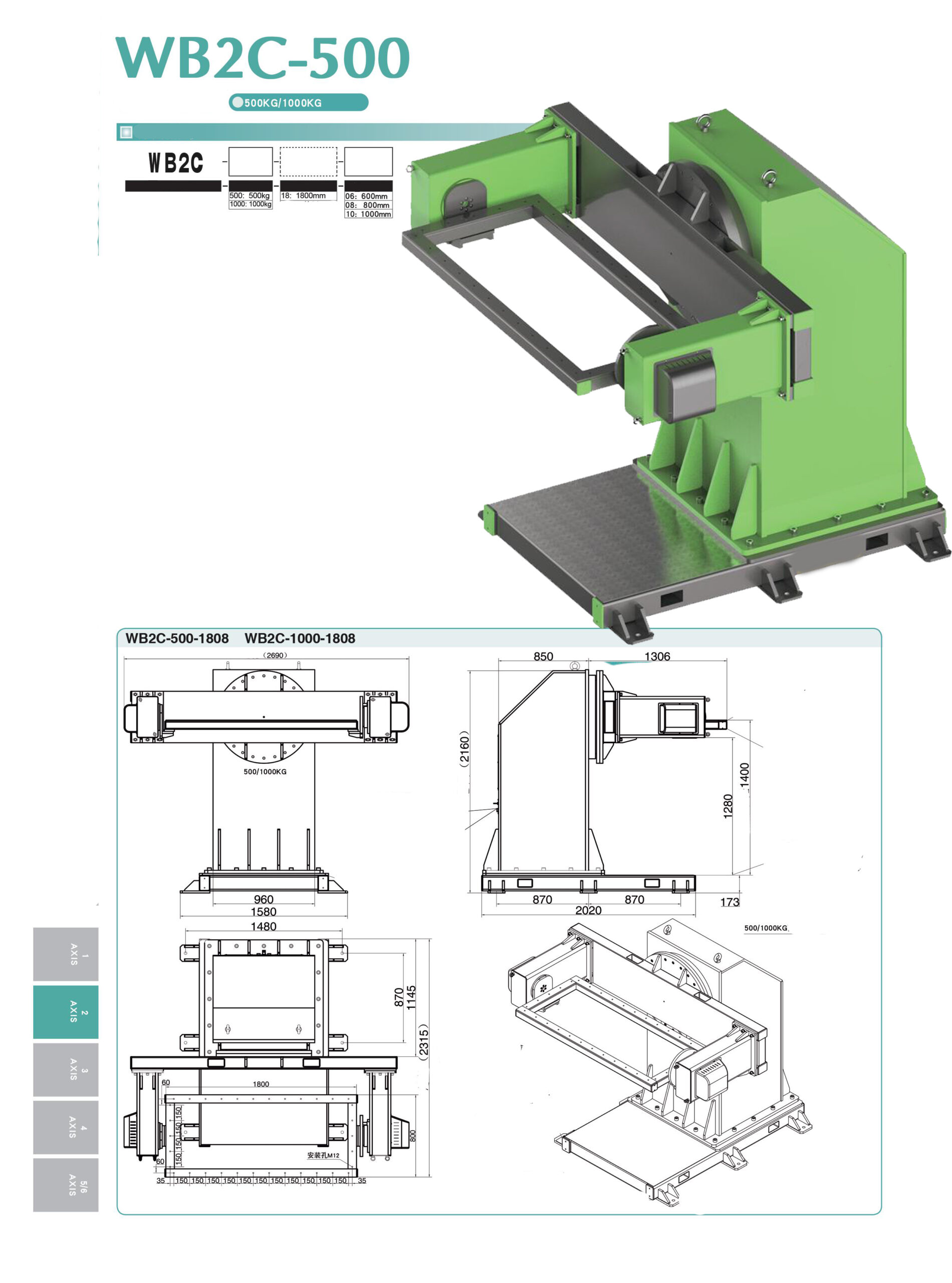

Additional equipment for grinding stations

We can equip robotic grinding stations with additional accessories. With the right selection of accessories, it is possible to increase the efficiency, safety and versatility of production processes.

Use of grinding stands

Robotising repetitive production is the key to increasing the efficiency, precision and reliability of your company's processes. Automated workstations eliminate errors, speed up tasks and ensure repeatable product quality. Our end-to-end solutions - from design to implementation and service - are fully tailored to the specifics of your production. By robotising repetitive processes, your company gains a competitive edge, saves time and optimises costs.

- Furniture industry

- Steel industry

- Metal casting

- Glass industry

- And wherever components are ground

- Pass-through 6 axles

- Stationary 6 axes

- Suspended 6 axes

- Suitable for machining steel, aluminium, etc.

- Oscillation of steel plates, stainless steel, aluminium etc.

- Polishing of furniture tops

- Surface sanding

- Edge-breaking

- Grinding of castings

- Grinding of welds

- Grinding cell

- Dust extraction

- Turntable

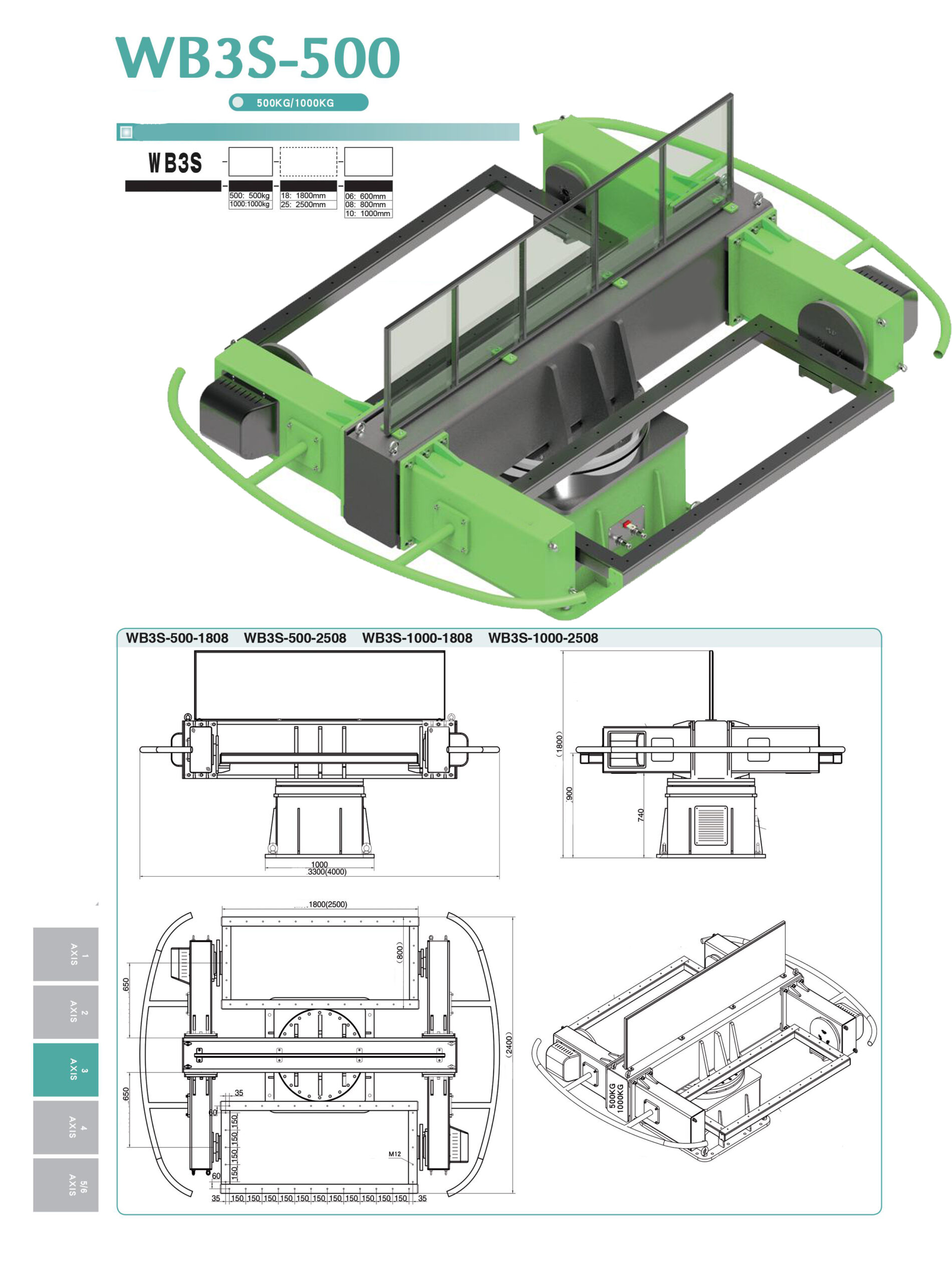

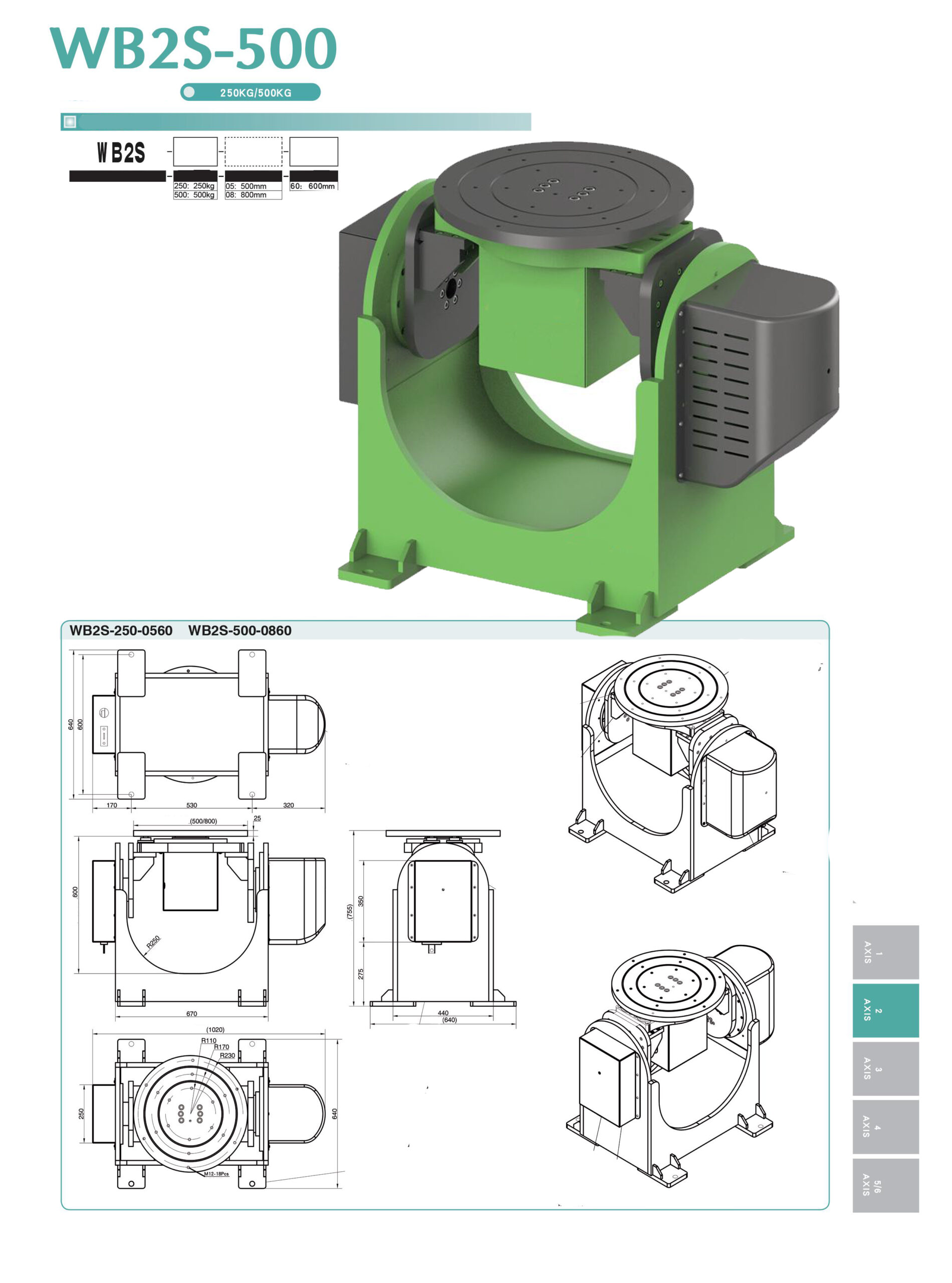

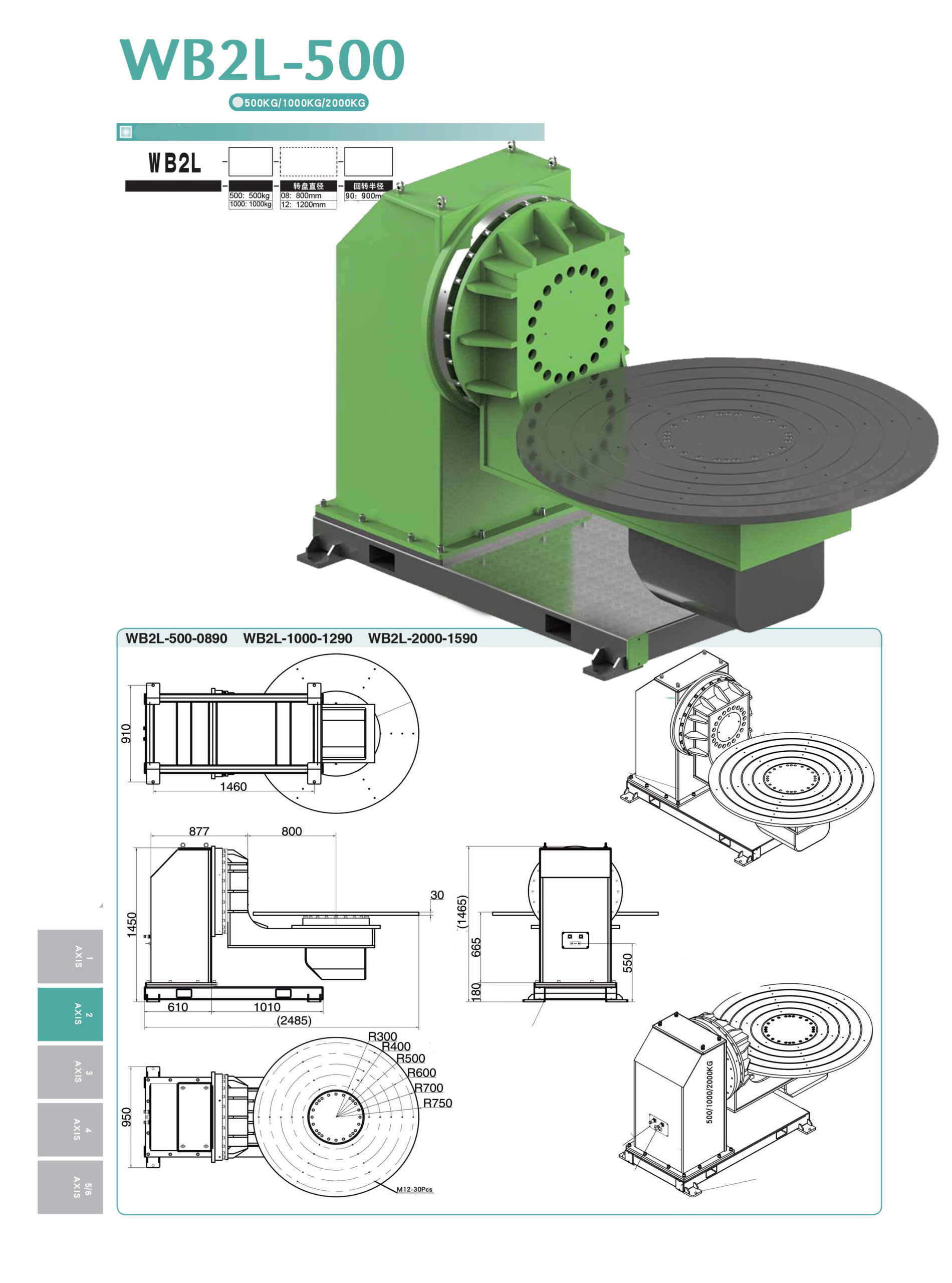

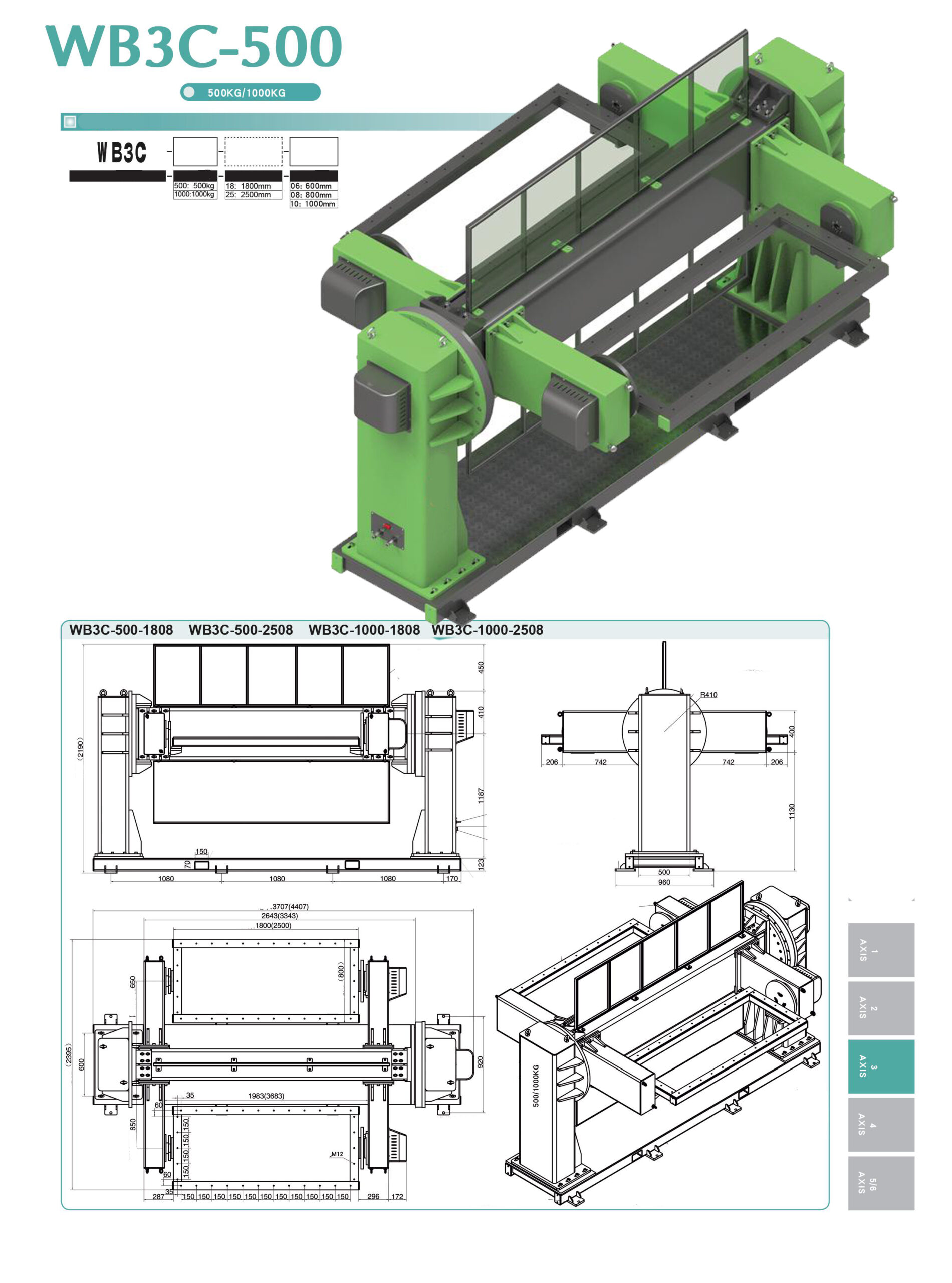

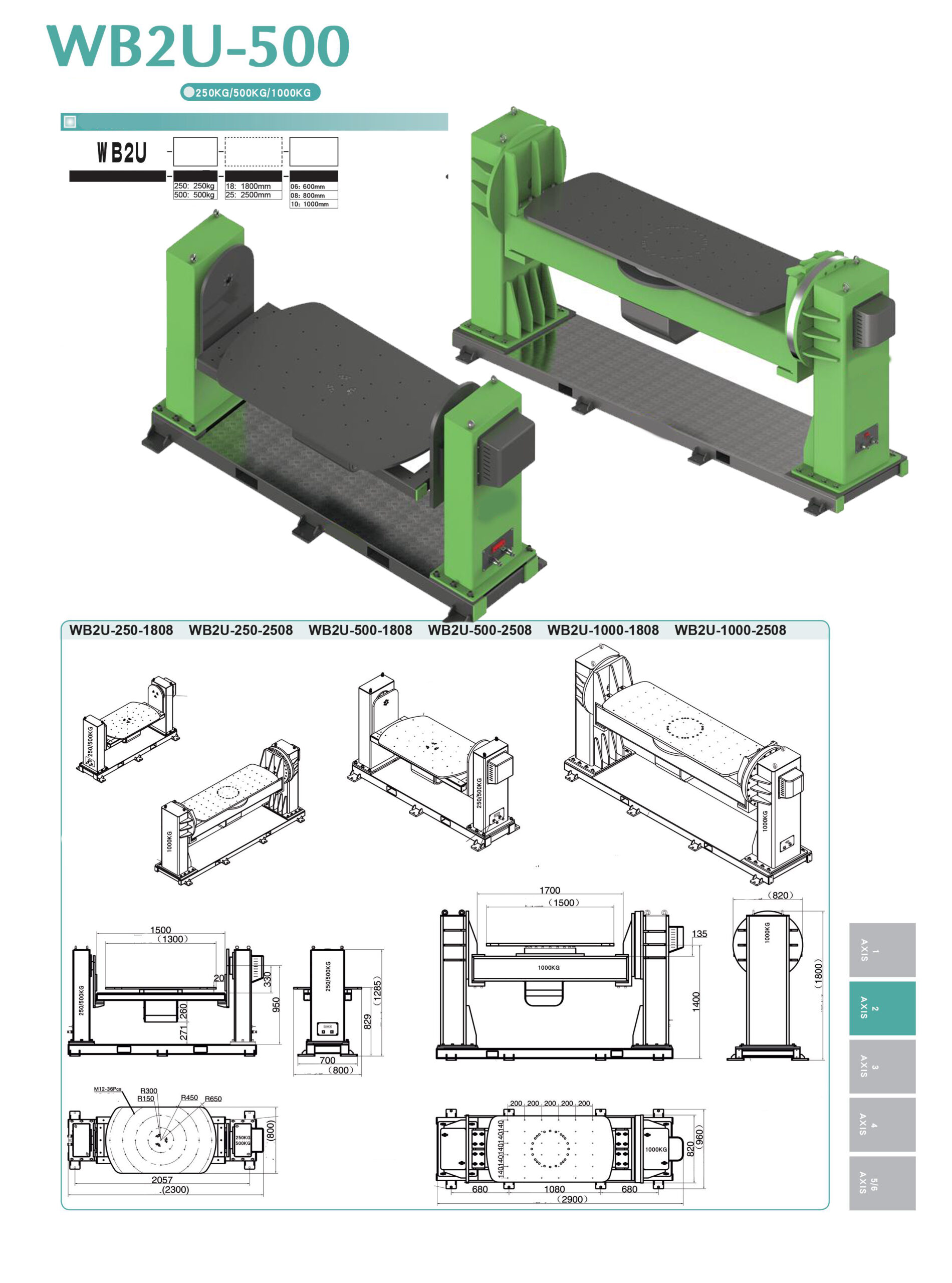

- Swivels and positioners

- 3 types of grinding heads

- Abrasive magazine for automatic abrasive collection

- Operating panel

- Protection fences

- Training

- Service

Customer feedback

Our blog

5 myths about the robotisation of manufacturing broken down into facts and figures

5 myths about manufacturing robotisation dispel stereotypes. Find out how automation increases efficiency and flexibility in every industry

Robotic welding: the future of industry

Robotic welding is the key to efficient production, increasing precision and production efficiency while reducing costs.

Ready for collaboration?

Make an appointment consultation

Don't wait any longer! Contact us today and find out how we can help your business reach new levels of productivity.

Contact details

Michale 88C

86-134 Dragacz

Answers to frequently asked questions

FAQ

How long does it take to install the stand?

Typical installation time is 3-6 months, depending on the scale of the project.

Are robots difficult to handle?

No, with a little training, your team will be able to manage robots effectively even without prior experience.

Can I adapt the system to different products?

Yes, our solutions are flexible and can be adapted to different types of products and packaging.

Which industries can benefit from your solutions?

Our systems are used, among others, in the food, steel and furniture industries, as well as wherever there is repetitive production.

Do you offer post-implementation technical support?

Yes, we provide full technical support as well as warranty and post-warranty service.