Robotic welding stations - complete solutions from design to service

We implement state-of-the-art welding workstations that combine Siasun's advanced robot technology with our many years of experience in building production lines. Welding robotisation is an investment that pays off!

Trust our experience - we build welding stations from A to Z

We offer proven robotic workstations for manufacturing industries

Comprehensive implementation of welding workstations tailored to your needs

Our company specialises in the design, construction and implementation of robotic welding stations that are fully customised to the customer's specific production. We offer:

- Customer needs analysis and advice

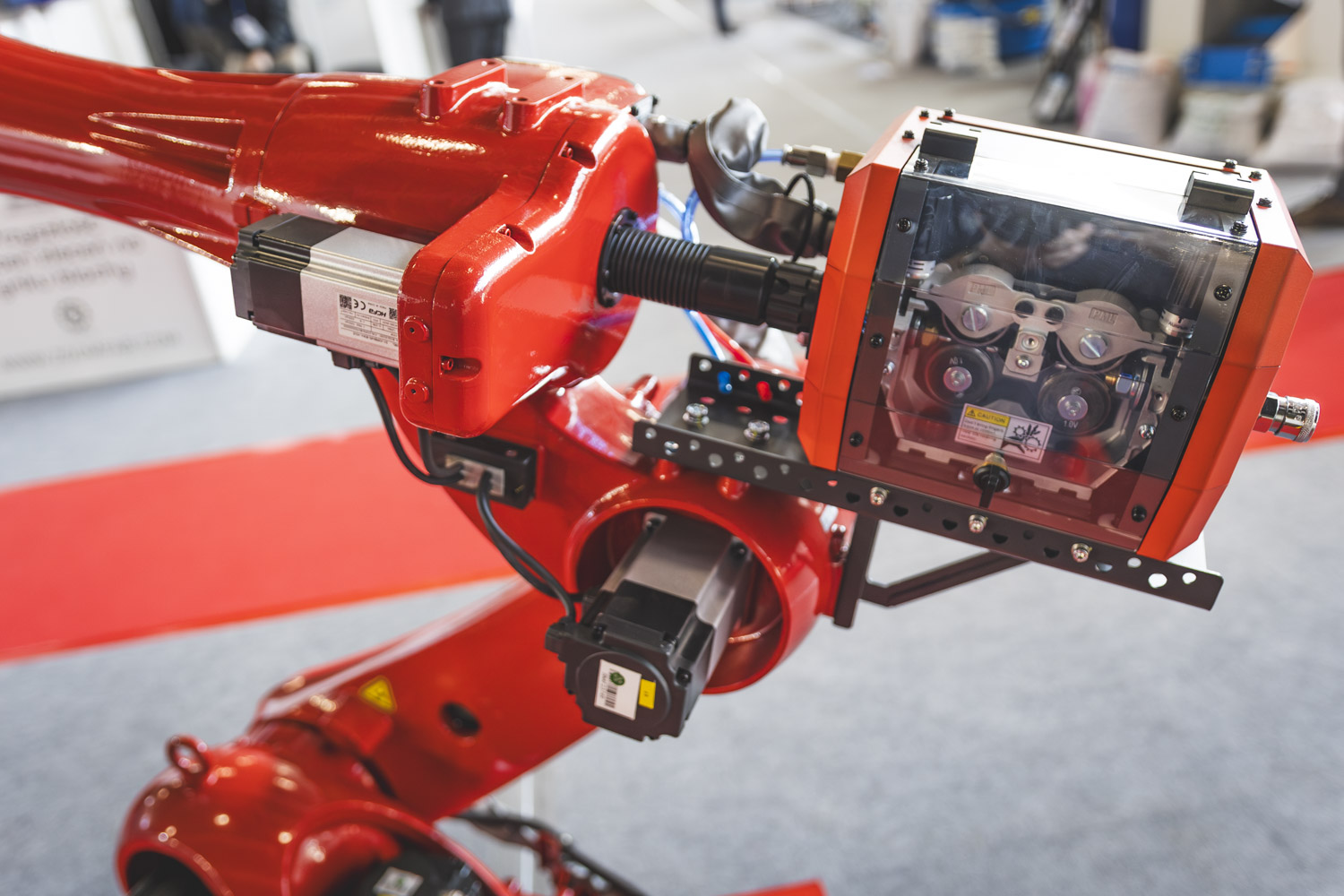

Selection of suitable Siasun robots and welding accessories.

Design of workstations according to customer requirements.

Integration with Megmeet welders or other equipment.

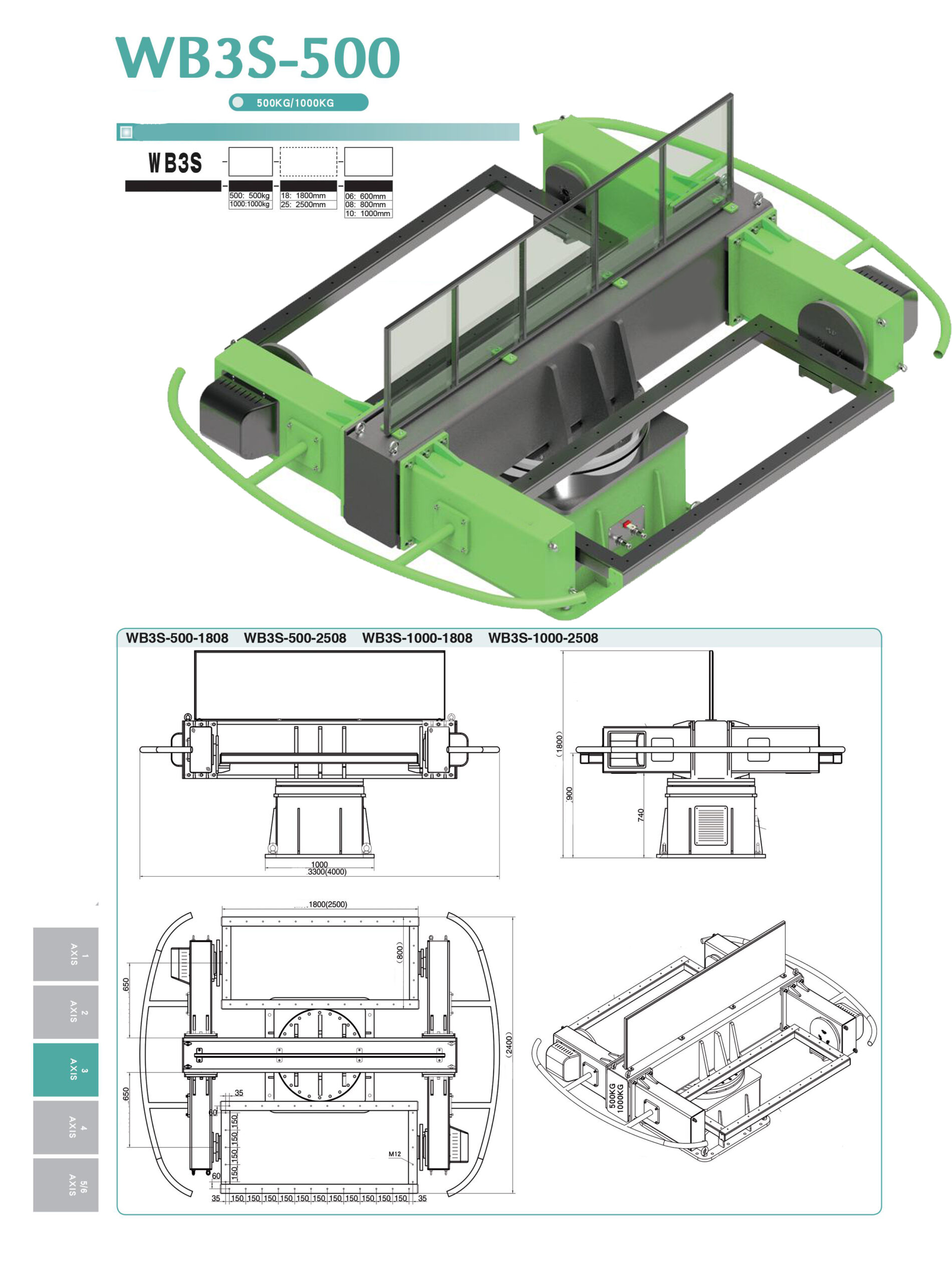

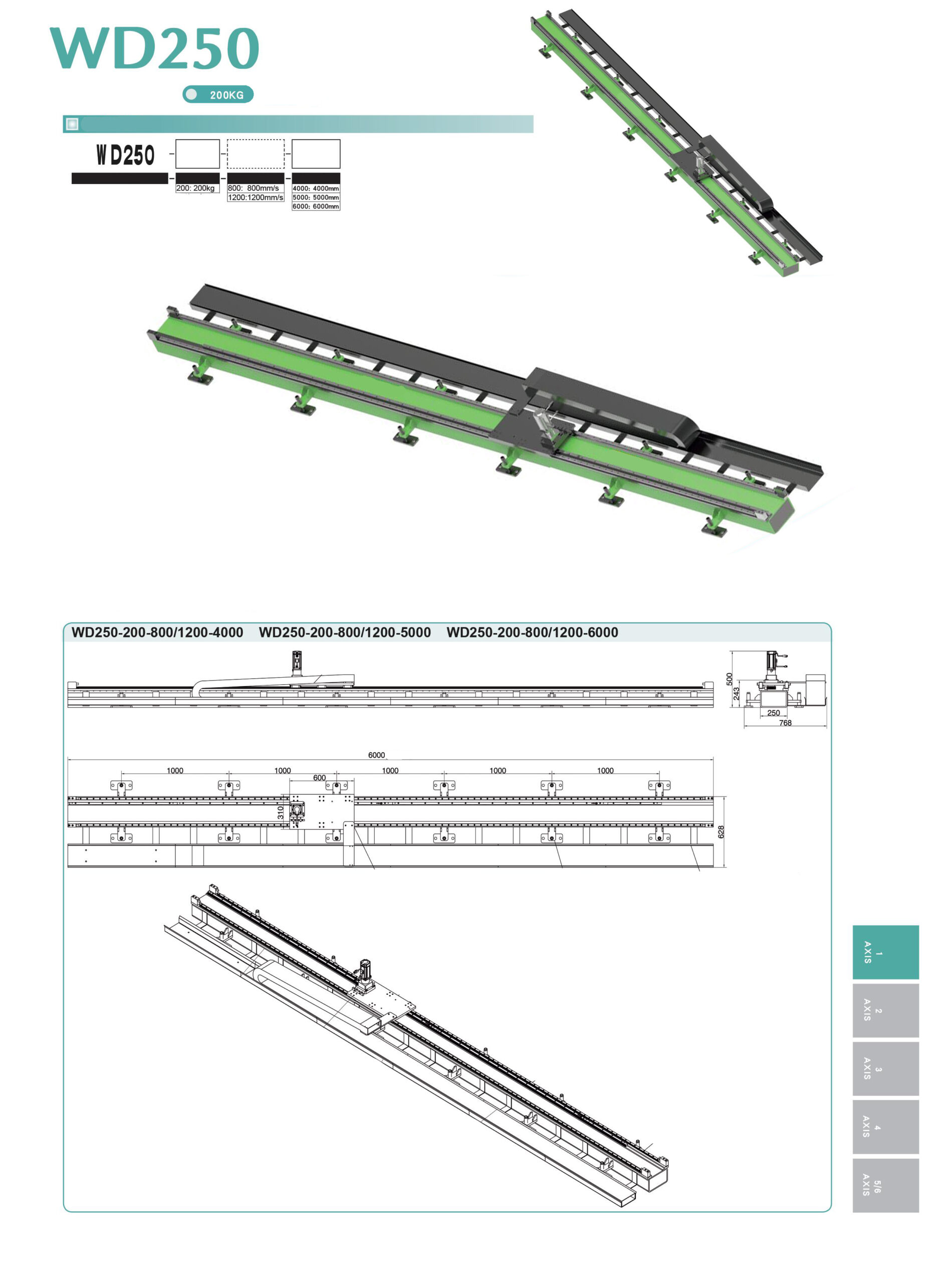

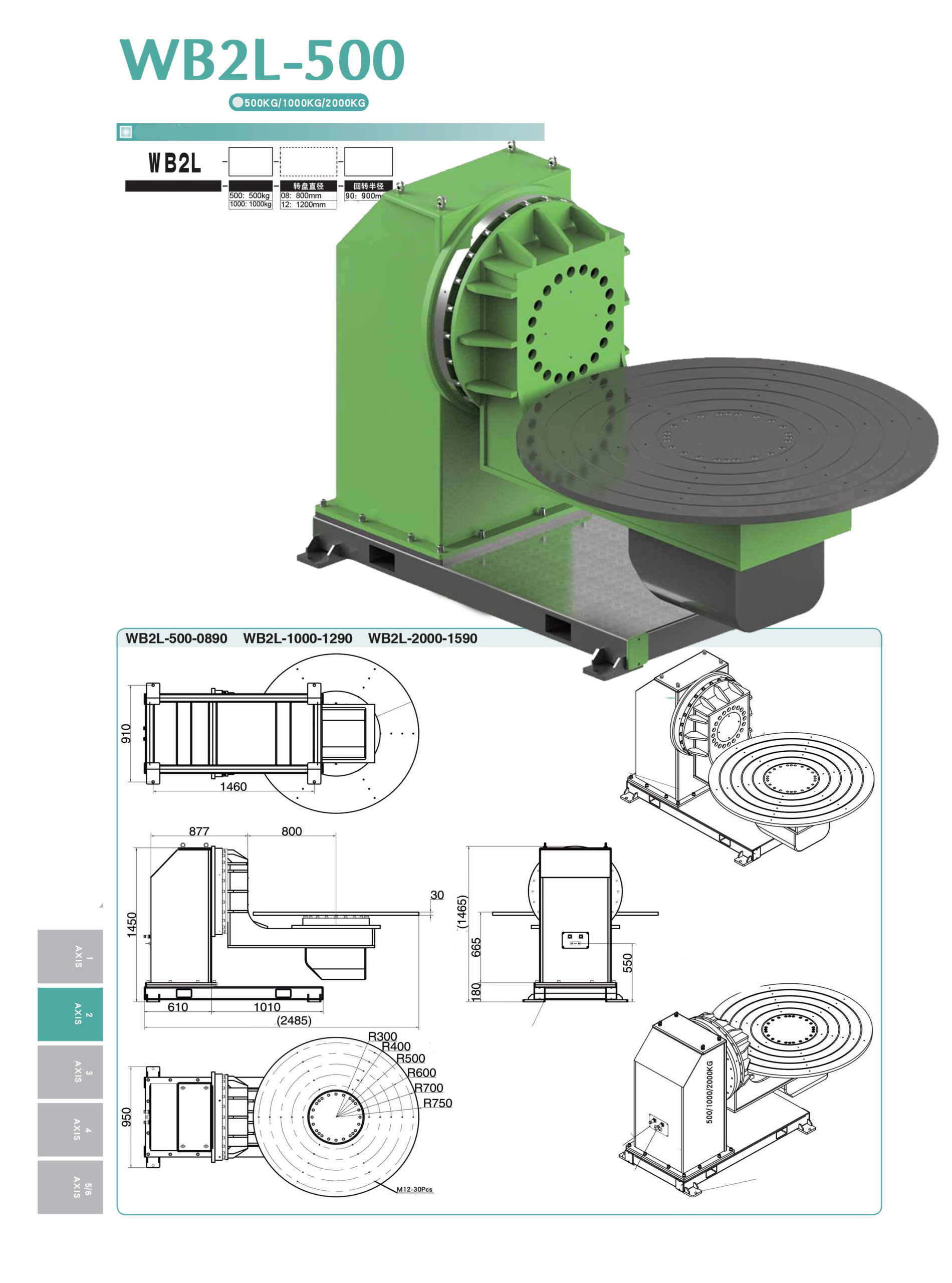

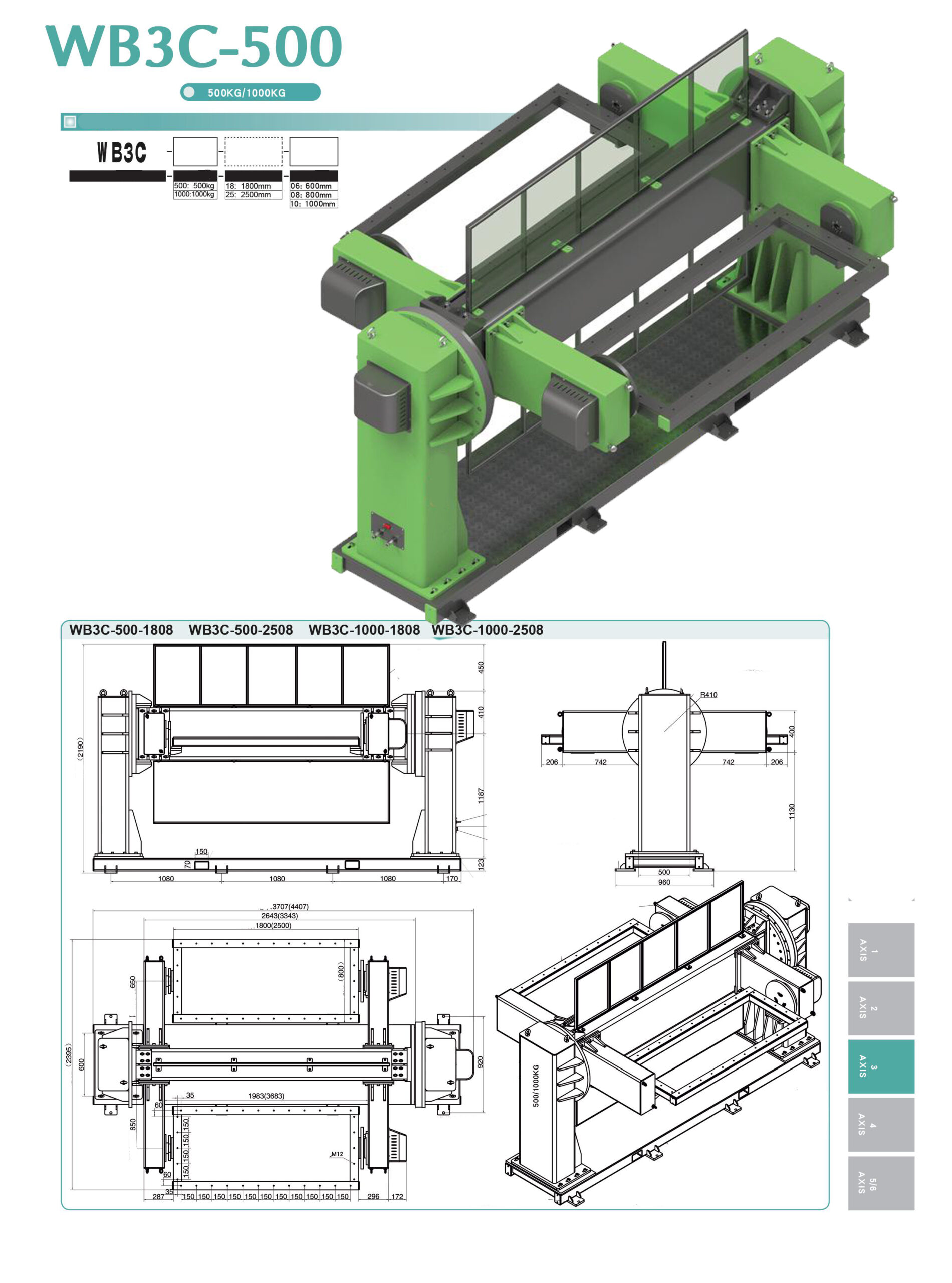

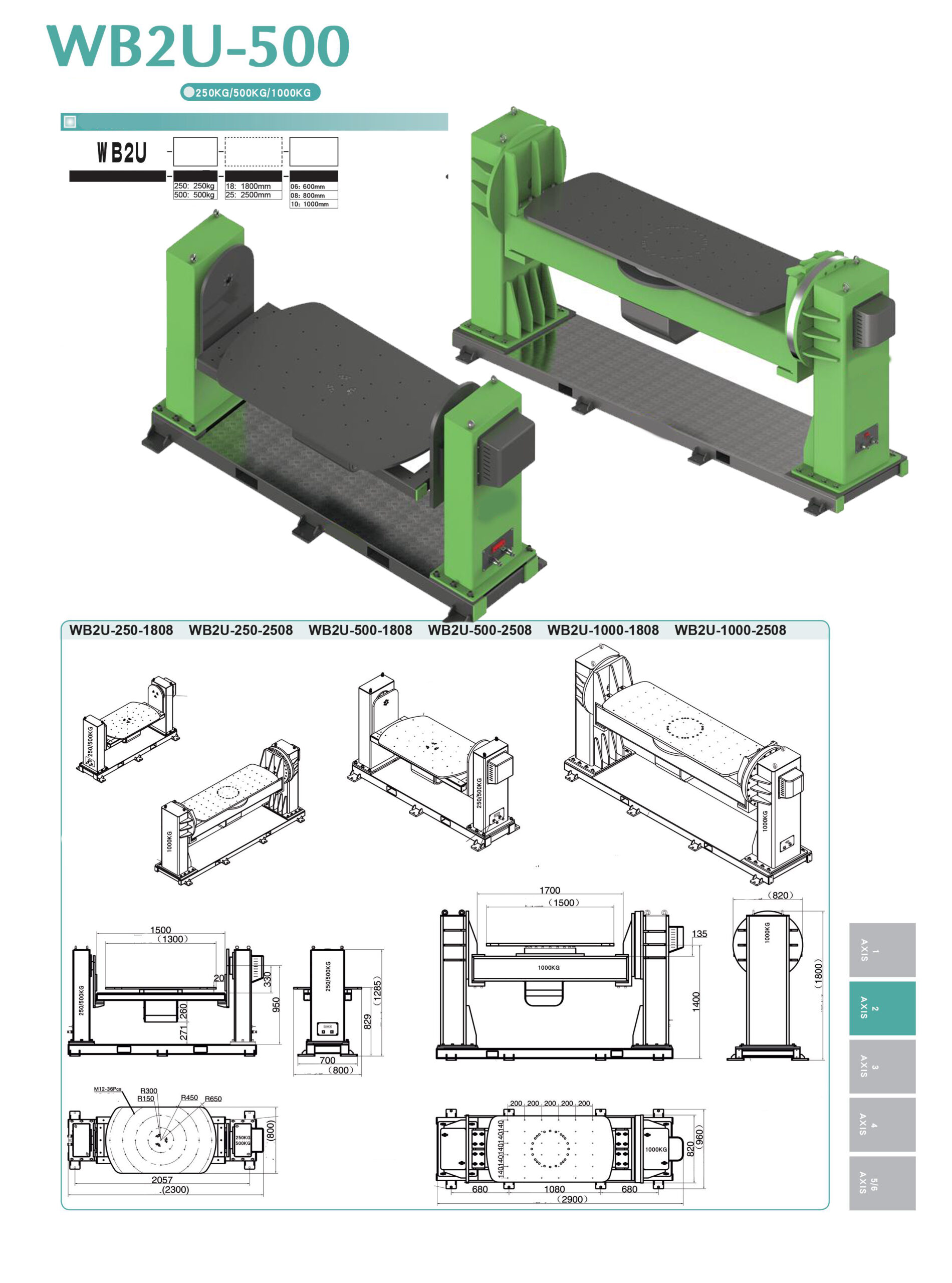

Construction of rotary tables, positioners and other bench components.

Programming of the robot and configuration of the entire system.

Installation and commissioning of the workstation at the customer's site.

Operator training and full technical support.

- Preparation of CE documentation

- Warranty and post-warranty service

Each station is designed from the ground up to ensure maximum efficiency, precision and safety in production.

Why choose our robotic workstations?

There are a number of benefits to implementing our solutions:

Efficiency gains: Robots work 24/7, eliminating downtime and increasing production efficiency.

Reducing labour costs: They replace several employees, allowing a faster return on investment - in as little as 1.5-2 years.

Quality improvement: The repeatability of the processes guarantees perfect weld quality without human error.

Occupational safety: Reduce the risk of accidents by automating difficult operations.

Production flexibility: Ability to adapt positions to changing market needs.

Our solutions are comprehensive - from design to service - eliminating the need to work with multiple suppliers.

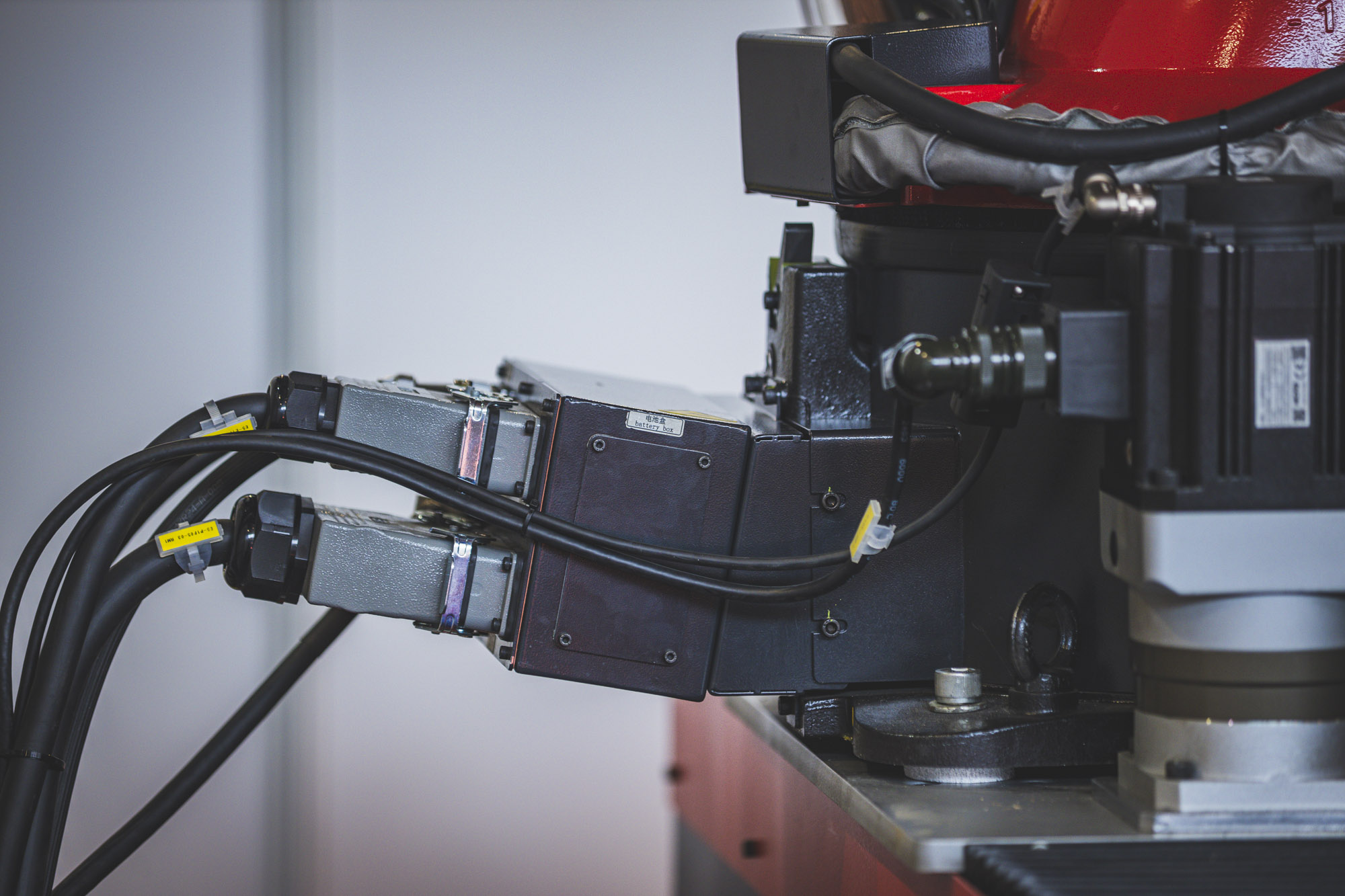

Siasun robots and years of experience in production line construction

Siasun robots are some of the best on the market - reliable, precise and economical. Thanks to our exclusivity in the Polish market, we offer them at an attractive price that ensures a quick return on investment. We combine this technology with our experience in designing and building large production lines, which allows us to create complete workstations tailored to the specific needs of the customer.

Realised projects - our business card

We are proud to present examples of our implementations that have helped our clients achieve tangible business benefits

Packaging system

6-head saw

Saw with feeder

Ready to implement robotic welding?

Don't wait any longer! Contact us today and find out how we can help your business reach new levels of productivity.

Make an appointment for a consultation

Robotised workstations

Why us?

We are a company that offers end-to-end construction of robotic workstations from A to Z, eliminating the need for external contractors and speeding up projects. Our experience in building production lines allows us to transfer proven solutions to modern robotic workstations, ensuring high quality and efficiency.

In addition, as the exclusive distributor of Siasun robots in Poland, we offer our customers access to market-leading robotic technology at more competitive prices, without having to compromise on quality and performance.

-

Experience in building production lines Years of experience in the design and construction of production lines allow us to implement proven and innovative solutions, tailored to the specific needs of the company.

-

Individual approach to the customer We understand that every business is different, which is why our solutions are always tailored to our clients' individual needs and business goals, ensuring maximum satisfaction.

-

Competitive prices Our solutions offer excellent value for money, so you can modernise your processes without going over budget.

-

Exclusivity for Siasun robots in Poland We are the only company in Poland to offer Siasun robots that combine unparalleled quality with attractive pricing, giving our customers exceptional value and a competitive advantage.

-

Guarantee and fast service We guarantee a fast service with a fair guarantee, safeguarding your investment and ensuring the uninterrupted operation of your production facility.

-

Comprehensive service We offer full support - from consultation to design to service - ensuring seamless implementations and business continuity.

Your production

at a new level

Here's how robotisation is changing the face of your business - concrete data that speaks for itself.

Tailor-Made Complex Stations

Wide range of technologies - we will find the optimal solution for your production

Our welding stations offer the flexibility to choose from a variety of welding technologies, allowing you to precisely tailor a solution to your specific production needs.

With our experience and knowledge, we will help you choose the technology that best optimises your production processes, increases productivity and quality.

Additional welding station equipment

We can equip robotised welding stations with additional accessories. With the right choice of accessories, it is possible to increase the efficiency, safety and versatility of production processes.

Return on Investment in Robotics Calculator

Investment costs

-Production parameters

+Staff parameters

+Economic parameters

+Calculating the results ...

Results of the combined analysis

Financial summary

Production analysis

Cost analysis

Long-term analysis

Results of employee savings analysis

Financial summary

Employee cost analysis

Long-term analysis

Results of the analysis of increased production

Financial summary

Production analysis

Long-term analysis

Attention: The results presented by the ROI calculator are indicative and for informational purposes only. The calculator has been designed to illustrate the potential opportunities and approximate return on investment for robotisation, but should not be the sole basis for making business decisions.

Actual results may differ significantly from the calculations presented due to numerous variables beyond our control, such as market fluctuations, changes in energy costs, unforeseen downtime, changes in legislation and taxation, or individual production process conditions.

We recommend treating the results of the calculator as a starting point for further, more detailed analyses, taking into account the specifics of your company.

Application of welding workstations

Robotising repetitive production is the key to increasing the efficiency, precision and reliability of your company's processes. Automated workstations eliminate errors, speed up tasks and ensure repeatable product quality. Our end-to-end solutions - from design to implementation and service - are fully tailored to the specifics of your production. By robotising repetitive processes, your company gains a competitive edge, saves time and optimises costs.

- Automotive industry

- Steel industry

- Shipbuilding industry

- And wherever there are welded components

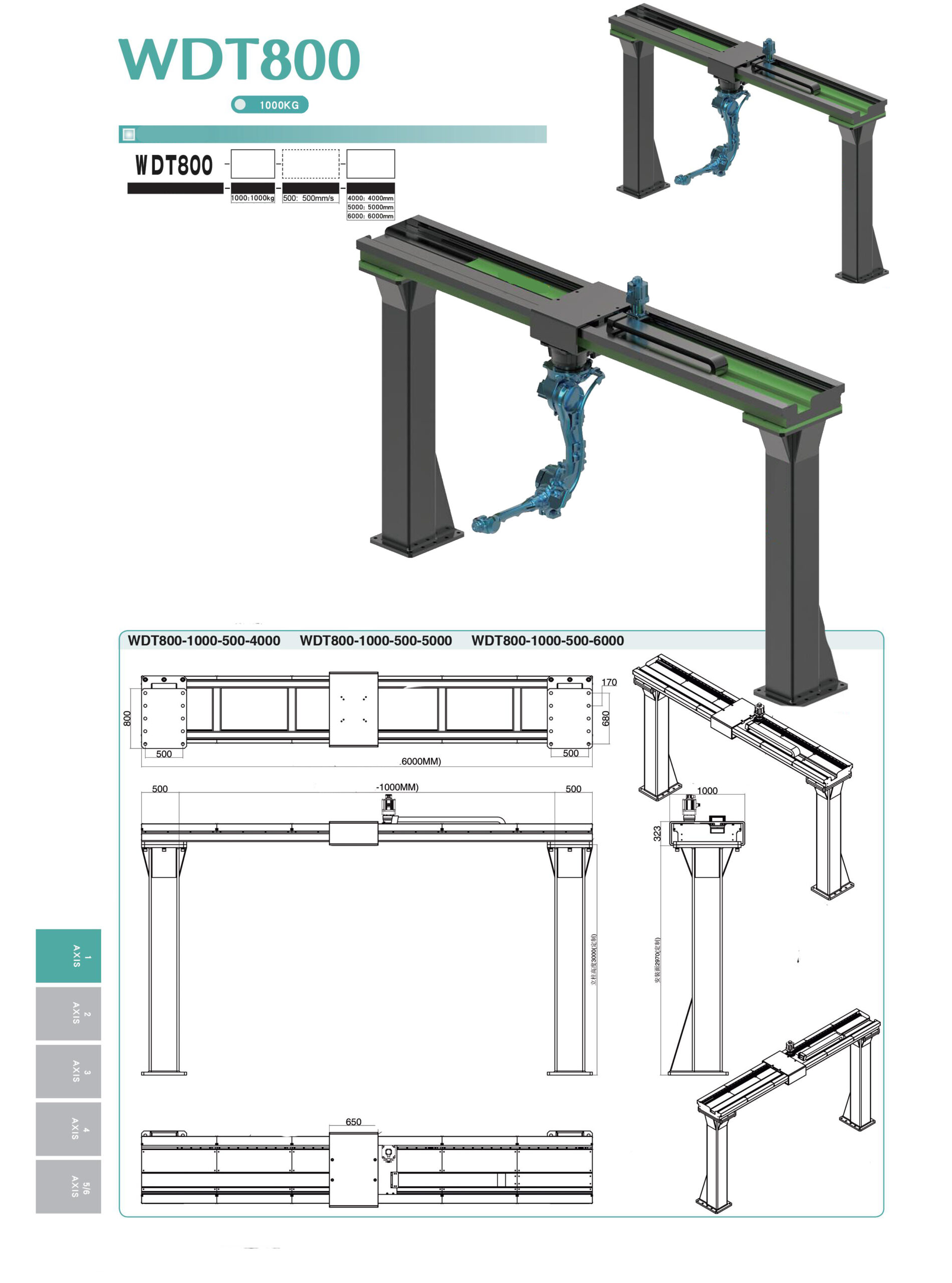

- Pass-through 6 axles

- Stationary 6 axes

- Suspended 6 axes

- Designed for welding carbon steel

- Designed for welding aluminium

- Designed for welding stainless steel

- Welding cell

- Automatic feeder

- Answering machine

- Cleaning station (burner preparation)

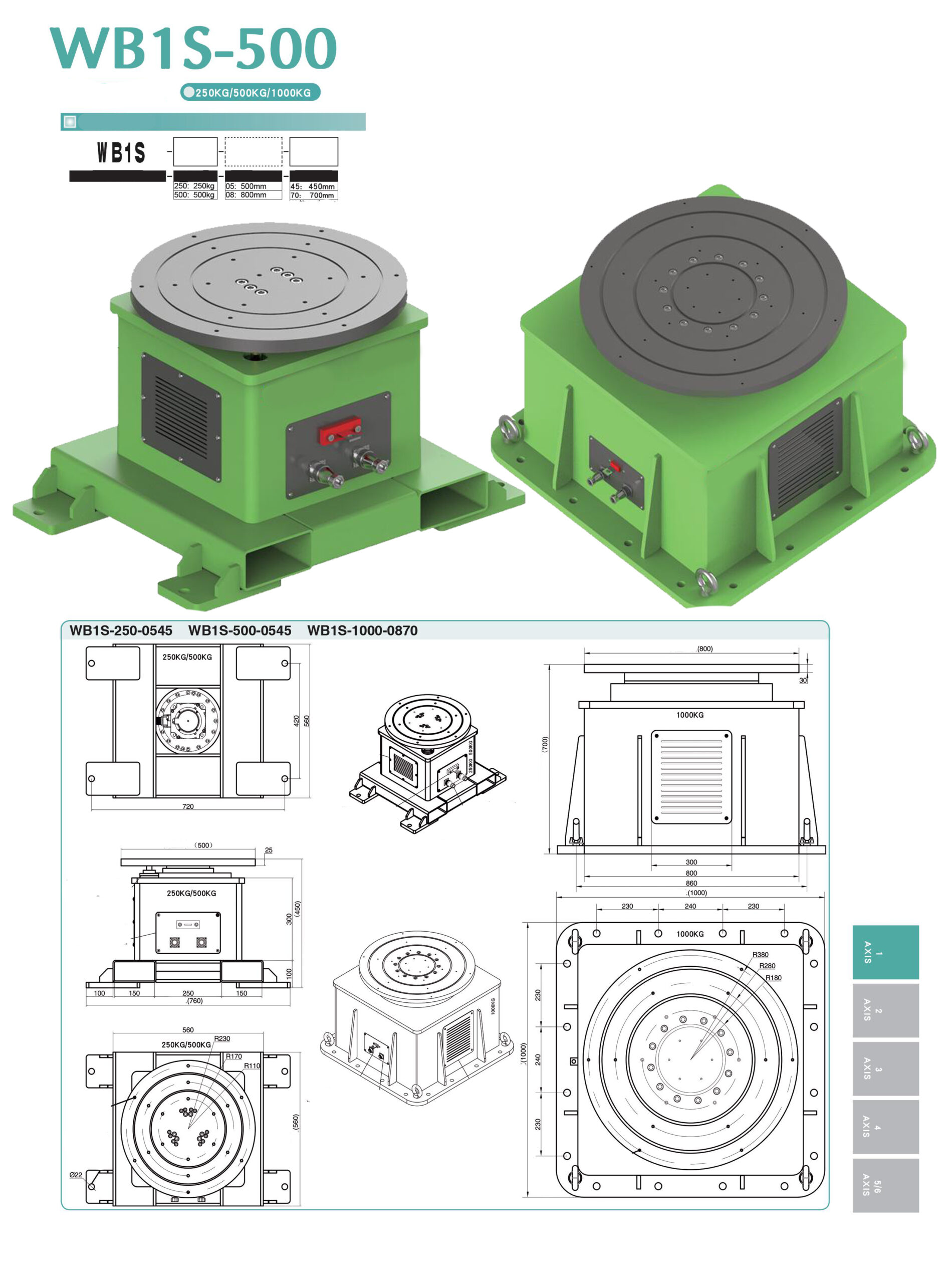

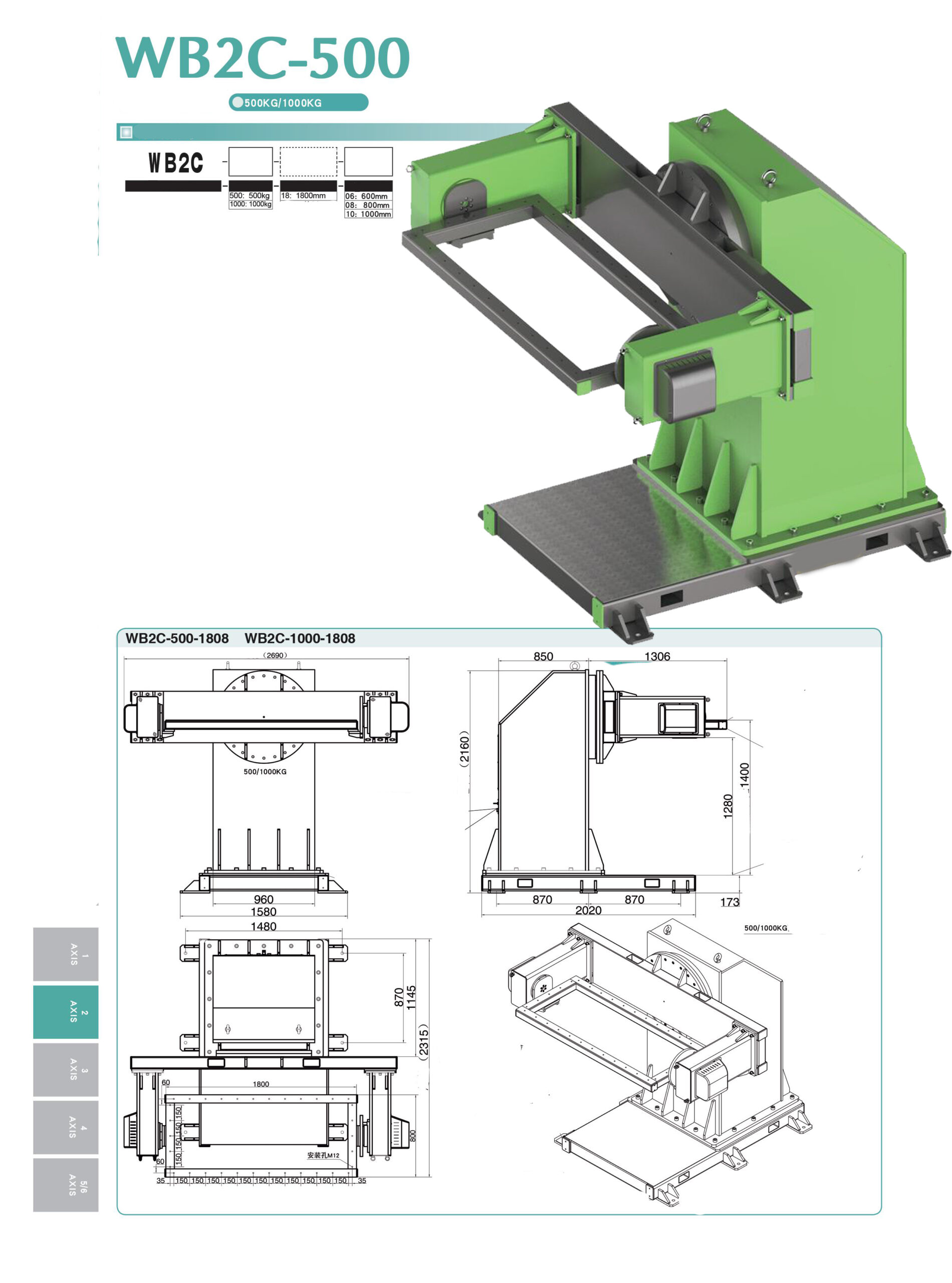

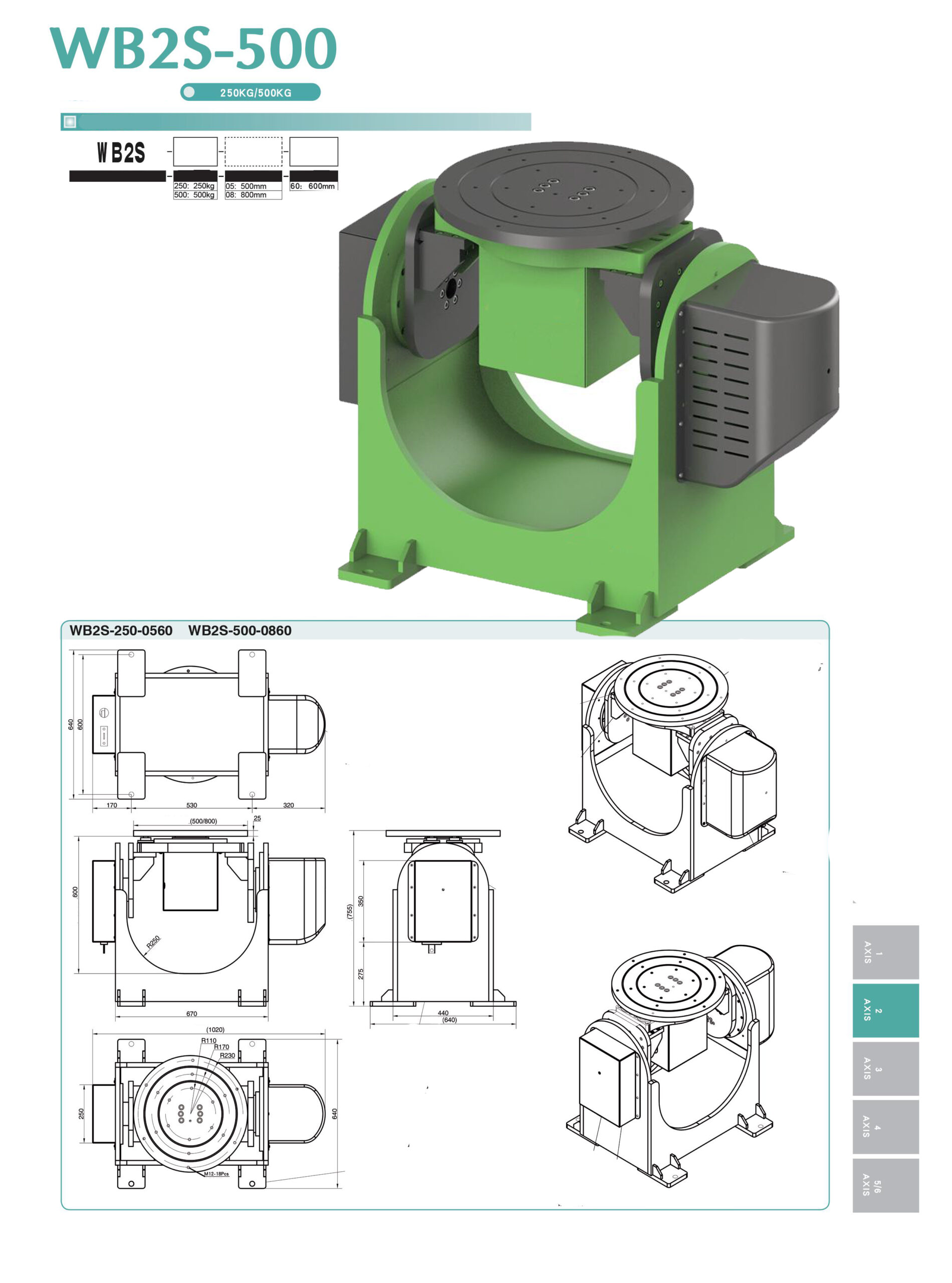

- Swivels and positioners

- Operating panel

- Robot base

- Protection fences

- Training

- Service

- Maintenance

Customer feedback

Our blog

5 myths about the robotisation of manufacturing broken down into facts and figures

5 myths about manufacturing robotisation dispel stereotypes. Find out how automation increases efficiency and flexibility in every industry

Robotic welding: the future of industry

Robotic welding is the key to efficient production, increasing precision and production efficiency while reducing costs.

Ready for collaboration?

Make an appointment consultation

Don't wait any longer! Contact us today and find out how we can help your business reach new levels of productivity.

Contact details

Michale 88C

86-134 Dragacz

Answers to frequently asked questions

FAQ

What distinguishes your robotic welding stations?

Our welding workstations are complete and customised. We provide a complete service from design to service and use high quality Siasun robots, making us the only ones in the market offering such solutions

What are the benefits of automating the welding process?

Welding automation increases production efficiency, reduces operating costs and improves weld quality by eliminating human error. With our robots, you can achieve a faster return on investment in as little as 1.5-2 years

How long does it take to install a robotic workstation?

Thanks to our holistic approach, we reduce the production time of a workstation from several months to just a few

What welding technologies do your robots offer?

Our robots support a wide range of welding technologies, including MIG/MAG, TIG, laser and plasma, allowing optimum adaptation to specific production needs

Do you offer technical support and service after installation?

Our robots are designed with ease of use in mind. After a short training session, your employees will easily be able to manage them, even without previous experience

Are robots difficult to handle?

Investment in our robots, including Siasun robots, is significantly more cost-effective than competing brands such as ABB or KUKA, meaning lower initial costs and a faster return on investment

What are the investment costs for a robotic welding station?

The process begins with a customer needs analysis and consultancy, followed by the design and construction of the workstation. Our services also include programming of the robot and training of personnel, providing comprehensive support from design to service.

Can I adapt the robots to my existing production system?

Yes, all our solutions can be integrated into your current production systems, allowing a smooth transition and minimising downtime