We build robotic workstations,

which increase efficiency

Everything in one place - from the design to the finished workstation. We will design, build, implement and train your team, providing solutions perfectly tailored to your production. We guarantee full service support to keep your business running without interruption.

Explore verified solutions

We offer proven robotic workstations for manufacturing industries

Robotisation - An Investment in the Future of Your Company

- Increased efficiency and productivity: Work 24/7 with complete precision and repeatability.

- Cost reduction: Faster return on investment through reduced labour costs - in as little as 1.5-2 years.

- Improving safety: Reduce the risk of errors and accidents in the workplace.

- Production flexibility: Adapt production lines to changing market needs.

- A more attractive workplace: Automated workstations reduce monotony and physical strain.

Robotised workstations

We specialise in the construction of robotic workstations, which combine our many years of experience in the construction of production lines with the latest robotics technologies.

Our workstations are designed with the specific needs of your plant in mind, ensuring unrivalled precision and productivity. By choosing our solutions, you are investing in the future of your production with a focus on quality, cost reduction and increased efficiency.

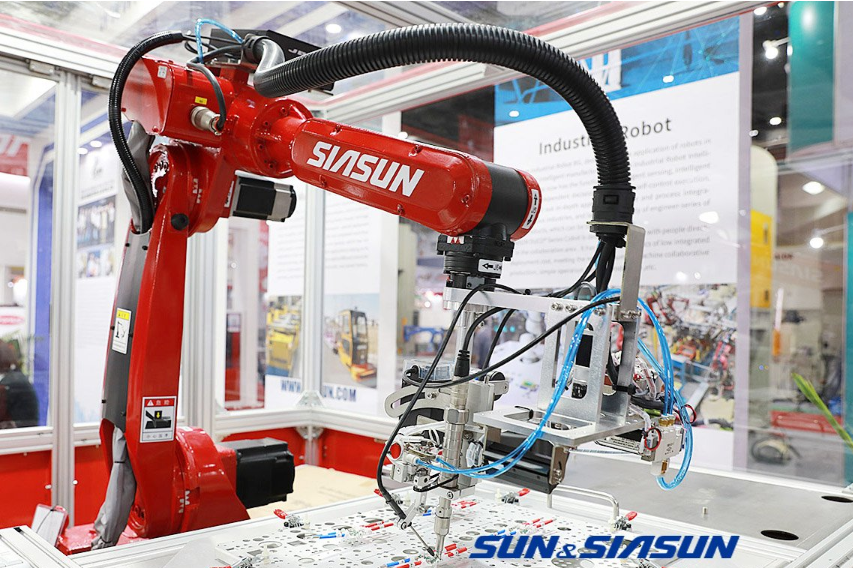

Siasun Robots - Exclusive on the Polish Market

Siasun robots, which are among the top robots in China, are now available to you thanks to our exclusivity in the Polish market.

Known for their reliability and high quality, they are widely used on production lines in the USA and Asia. We offer them at an attractive price, a competitive alternative to competing brands.

Features List

Why us?

We are a company that offers end-to-end construction of robotic workstations from A to Z, eliminating the need for external contractors and speeding up projects. Our experience in building production lines allows us to transfer proven solutions to modern robotic workstations, ensuring high quality and efficiency.

In addition, as the exclusive distributor of Siasun robots in Poland, we offer our customers access to market-leading robotic technology at more competitive prices, without having to compromise on quality and performance.

-

Experience in building production lines Years of experience in the design and construction of production lines allow us to implement proven and innovative solutions, tailored to the specific needs of the company.

-

Individual approach to the customer We understand that every business is different, which is why our solutions are always tailored to our clients' individual needs and business goals, ensuring maximum satisfaction.

-

Competitive prices Our solutions offer excellent value for money, so you can modernise your processes without going over budget.

-

Exclusivity for Siasun robots in Poland We are the only company in Poland to offer Siasun robots that combine unparalleled quality with attractive pricing, giving our customers exceptional value and a competitive advantage.

-

Fair warranty and fast service We guarantee a fast service with a fair guarantee, safeguarding your investment and ensuring the uninterrupted operation of your production facility.

-

Comprehensive service We offer full support - from consultation to design to service - ensuring seamless implementations and business continuity.

Your production

at a new level

Here's how robotisation is changing the face of your business - concrete data that speaks for itself.

Tailor-Made Complex Stations

Our services

We offer solutions tailored to the needs of the manufacturing industry

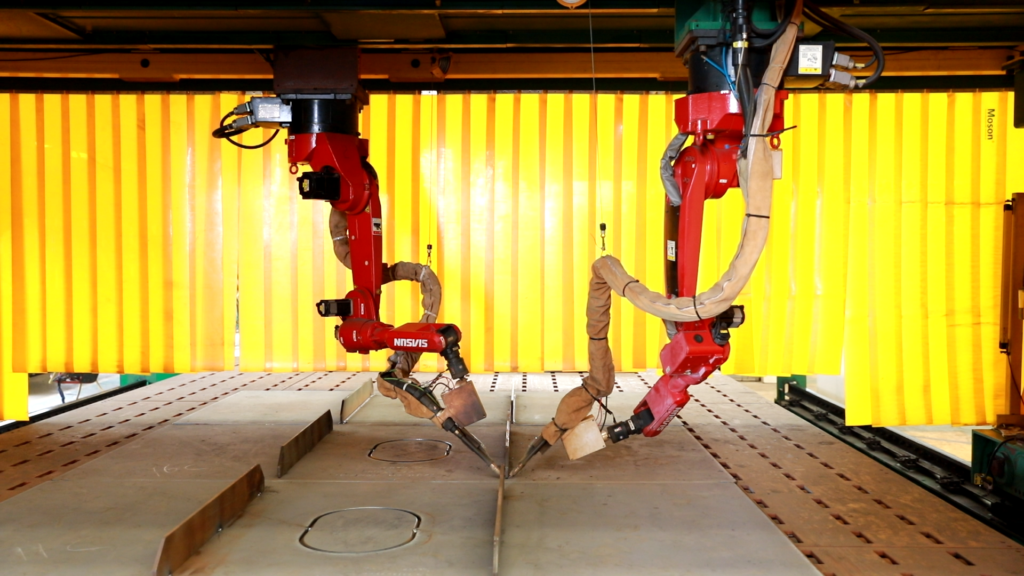

Robotisation of welding

Robotised welding is a state-of-the-art solution that combines precision, productivity and safety. With robotic welding stations, you will achieve reproducible weld quality, speed up production processes and reduce operating costs. Our end-to-end approach - from design to implementation - ensures that each solution is perfectly tailored to the specifics of your production. We will also take care of your team's training and service support to ensure continuous operation and system reliability.

Welding robotisation eliminates human error, ensuring the perfect quality of every weld. By automating your processes, you will achieve repeatability and reliability in every project.

Robotic welding systems allow you to work faster while reducing material and energy consumption. This is a saving that translates into greater competitiveness for your company.

Automatic welding workstations minimise the risk to workers by performing difficult and dangerous tasks. We guarantee reliable solutions that increase safety in the workplace.

Robotisation of packaging

Robotisation of packaging is key to streamlining logistics and production processes. Automated packing stations increase productivity, precision and speed of order processing, eliminating errors and reducing costs. Our comprehensive solutions are tailored to your specific production, from design to implementation, training and service. With packaging automation, your company gains reliability and a competitive advantage in the market.

Robotic packaging systems speed up order processing, allowing you to handle more products in less time. It's a solution that increases the operational efficiency of your business.

Packaging automation guarantees accuracy in every step of the process - from sorting to final packaging. This avoids mistakes that can generate additional costs.

Our solutions are designed to fit the diverse products and requirements of your industry. Robotic packaging stations provide scalability and easy adaptation to changing market needs.

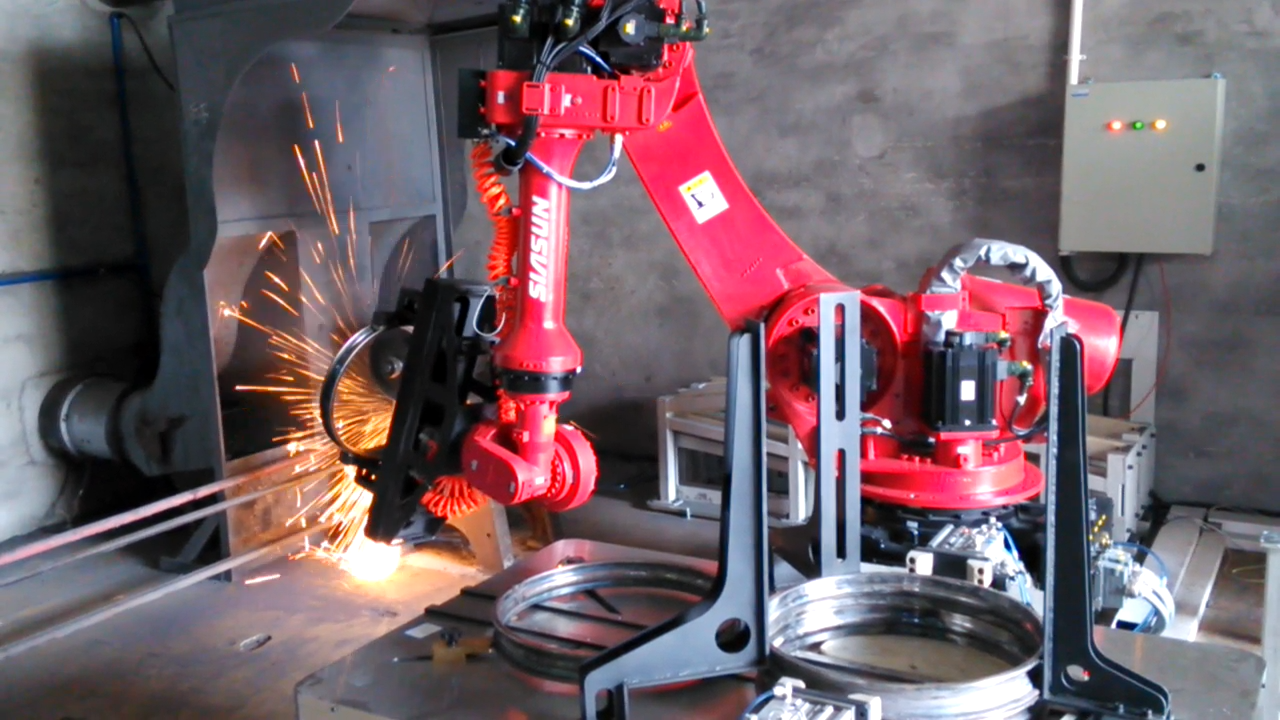

Robotisation of grinding

Robotised grinding means precision and efficiency at the highest level. Automated grinding stations ensure repeatability, eliminate errors and significantly speed up surface treatment processes. Our comprehensive approach includes design, construction, implementation and service, ensuring that each solution is perfectly tailored to your specific production. With robotic grinding, your company gains higher quality, time savings and greater employee safety.

Robotised grinding systems guarantee a precise and reproducible finish on every surface. Thanks to automation, you will get the perfect result, regardless of the scale of production.

Automatic grinding stations significantly speed up machining processes, allowing you to complete more tasks in less time. This is a cost saving that increases the efficiency of your business.

Robotisation of grinding eliminates the need for workers to perform heavy and monotonous tasks. Automated systems increase workplace safety and reduce the risk of injury.

Robotisation of laying

Stacking robotisation is a state-of-the-art solution that allows products to be stacked accurately, quickly and efficiently on pallets, racks or elsewhere. The use of robots eliminates human error, improves the quality of the process and increases productivity. Our end-to-end approach - from design to implementation and service - ensures that the systems are tailored to the specifics of your production. With robotic stacking, your company gains reliability, time savings and work safety.

Robots stack products with the highest accuracy, eliminating errors associated with the manual process. By automating stacking, you minimise the risk of damage and improve the quality of transport and storage.

The robotic stacking stations operate continuously, providing a fast workflow with no downtime. This solution allows for efficient use of resources and increased production scale.

Robotisation of paving eliminates the need for workers to perform heavy and monotonous tasks. Automated systems increase safety in the workplace, protecting people from injury and physical strain.

Painting Robotics

Robotisation of painting is a guarantee of precise finishing, high-quality coatings and material savings. Automated painting systems ensure repeatability, eliminate errors and speed up production processes. Our comprehensive approach - from design to implementation and service - allows us to tailor solutions to your specific production. With robotic painting, your company gains efficiency, reliability and a competitive edge.

Robotic painting systems guarantee even and precise surface coverage. Thanks to automation, you will achieve a reproducible quality finish regardless of the volume of production.

Painting robots optimise paint and varnish consumption, minimising material waste. Speeding up the painting process allows more jobs to be completed in less time.

Automated painting eliminates the need to work in harsh conditions, such as contact with chemical fumes. Robots increase worker safety and keep the workplace clean.

Robotisation of repetitive production

Robotising repetitive production is the key to increasing the efficiency, precision and reliability of your company's processes. Automated workstations eliminate errors, speed up tasks and ensure repeatable product quality. Our end-to-end solutions - from design to implementation and service - are fully tailored to the specifics of your production. By robotising repetitive processes, your company gains a competitive edge, saves time and optimises costs.

Robotic production systems guarantee identical quality for each product, eliminating errors resulting from manual processes. This solution ensures stability and reliability in every production cycle.

Automating repetitive processes allows production to be significantly accelerated, enabling more orders to be fulfilled in less time. This is a saving that increases operational efficiency.

Robotisation reduces operating costs by minimising material waste, reducing errors and using human and technological resources more efficiently.

Customer feedback

Our blog

5 myths about the robotisation of manufacturing broken down into facts and figures

5 myths about manufacturing robotisation dispel stereotypes. Find out how automation increases efficiency and flexibility in every industry

Robotic welding: the future of industry

Robotic welding is the key to efficient production, increasing precision and production efficiency while reducing costs.

Answers to frequently asked questions

FAQ

What sets your robotic workstations apart from the competition?

Our workstations are designed and built entirely in-house, ensuring consistency and customisation to meet specific customer needs. We are also distinguished by our unique exclusivity for the distribution of Siasun robots, which allows us to offer advanced technology at more competitive prices

Are robots difficult to handle?

No, our robots are designed with ease of use in mind. After a short training session, your team will be able to manage them effectively, even without previous experience

In which industries can your robots be used?

Our robots can be implemented in a wide range of industries, such as welding, palletising, grinding and wherever there is repetitive production

What is the process of purchasing and implementing robots like?

The process begins with a customer needs analysis and consultancy, followed by the design and construction of the workstation. Our services also include programming of the robot and training of personnel, providing comprehensive support from design to service.

How long does it take to install a robotic workstation?

Thanks to our method of integrating the overall process into one company, we are able to reduce the time it takes to build a stand from several months to just a few.

Do you offer post-installation technical support?

Yes, we provide full technical support and warranty and post-warranty service to ensure the continued efficiency of your production

May I see examples of your implementations?

Of course, we are happy to provide case studies and testimonials from our satisfied customers, including details of specific projects

Ready for collaboration?

Make an appointment consultation

Don't wait any longer! Contact us today and find out how we can help your business reach new levels of productivity.

Contact details

Michale 88C

86-134 Dragacz